- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

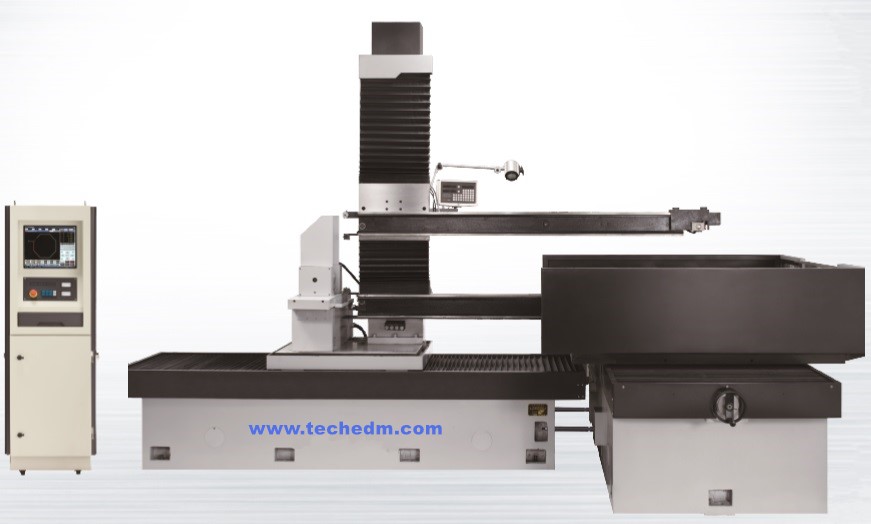

II. Features: WITH THE BEST CONTROL

SYSTEM

1. Lowest running cost

2. Reusable molybdenum wire

3. Multiplicity cutting function: better accuracy, better surface finishing

4. DXF, AutoCAD can be read. AutoCAD can be used directly, easier to operate

5. Surface finishing 1.0-0.8μ

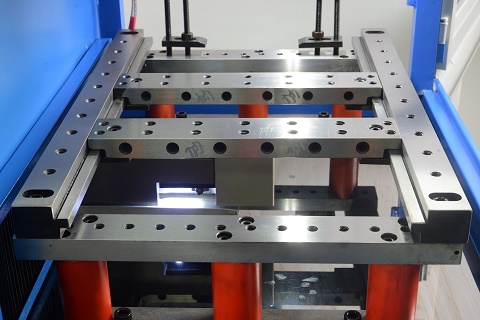

6. The casting for the main machine bed is equipped with the high rigid

HT250, which made by a famous Japanese manufacturer. Integrated structure

design, all casting parts are made with the procedure of resin-send and twice

heat treatment to improve the max load weight and keep a good precision for

long time and avoid the distortion.

7. Panasonic fromJapan

8. New designed three layer filter coolant system

9. Industrial computer: more stable, longer using life

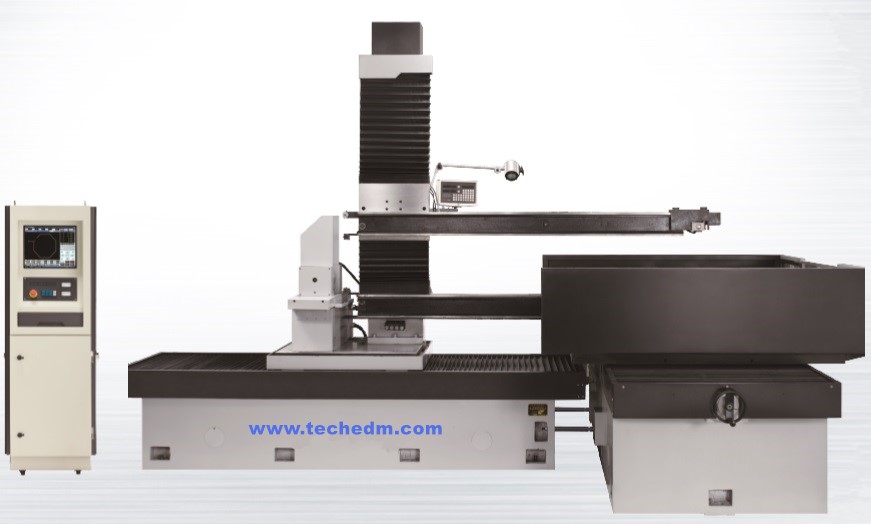

III. CONTROL SYSTEM Windows XP (installed

with Auto cut )

1. The controller

equipped the Auto cut Intelligent software, which integrates the program and

control and based on Windows XP. This new designed Auto cut software is the

unique software for WEDM running on the condition of windows XP.

(1)Coordinate system: Absolute coordinate, incremental coordinate (relative

coordinate)

(2) Functions of coordinate transforming, zooming in and zooming out,

rotating and tracking display in real time

(3)Functions of interpolation of straight line and circular arc

(4)Function of taper processing: As above

(5)Function of processing different top and bottom abnormities parts

(6)Auto-handle for short circuit and wire-break

(7)Functions of memorizing: unexpected power off, it can continue the

processing automatically; auto-stop after processing

(8)Functions of auto edge-touching position and auto center finding

(9)Function of auto-adding transitional arc (Arbitrary angle)

(10) Functions of menu technology and auto-programming ward

(11)Functions of menu technology and auto-programming

(12)AUTOCAD can be used to program directly in the software.

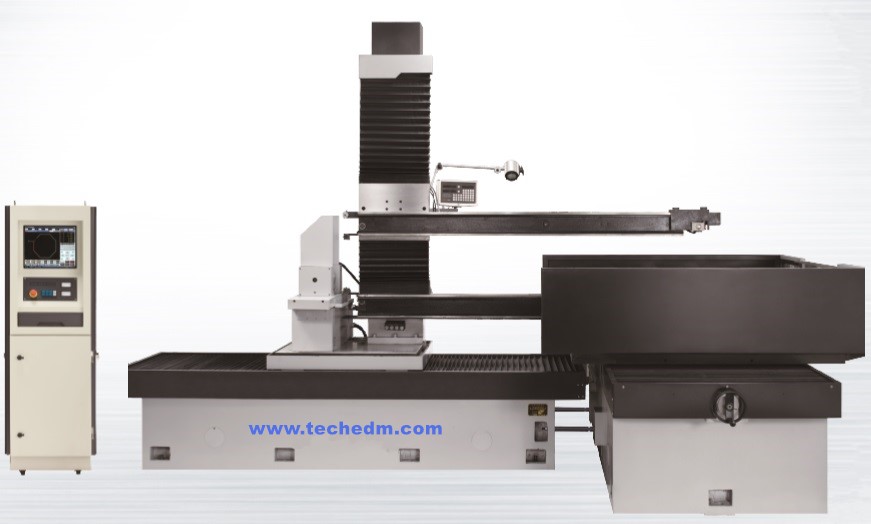

2.

Using the PCI slot controller card, LCD Monitor and the High-tech Industrial

computer. That greatly enhances the stability of control and greatly reduces

the computer the failure rate.

3.

Embedded Control system can be connected with many design software

smoothly.

4.

Variety of pulse power can be chosen, which is suited for a number of

processing conditions to improve the cutting ability of the high precision

parts.

5.

Parameters Automatically created according to the work piece

6.

CNC system configuration and technical performances

(1)

CNC Hardware configuration:

(2)CNC

software and operation platform:

(3)CNC

technical function:

(4)Running

environment

(A)

Industrial Computer:P4 or above

(B)EMS

memory:4GSSG

(C)Fixed Disk:160G

(D)USB

and Internet

(E) 15″liquid crystal display (LCD)

(F) Keyboard and mouse

(A)

CNC Auto-program and control function

(B)

operation platform: Windows XP

(A) 4

axis processing

(B)Function of processing different top and bottom abnormities parts

(A)

Temperature: 5-40 degree

(B)

Relative humidity:40%~80%.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap