- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

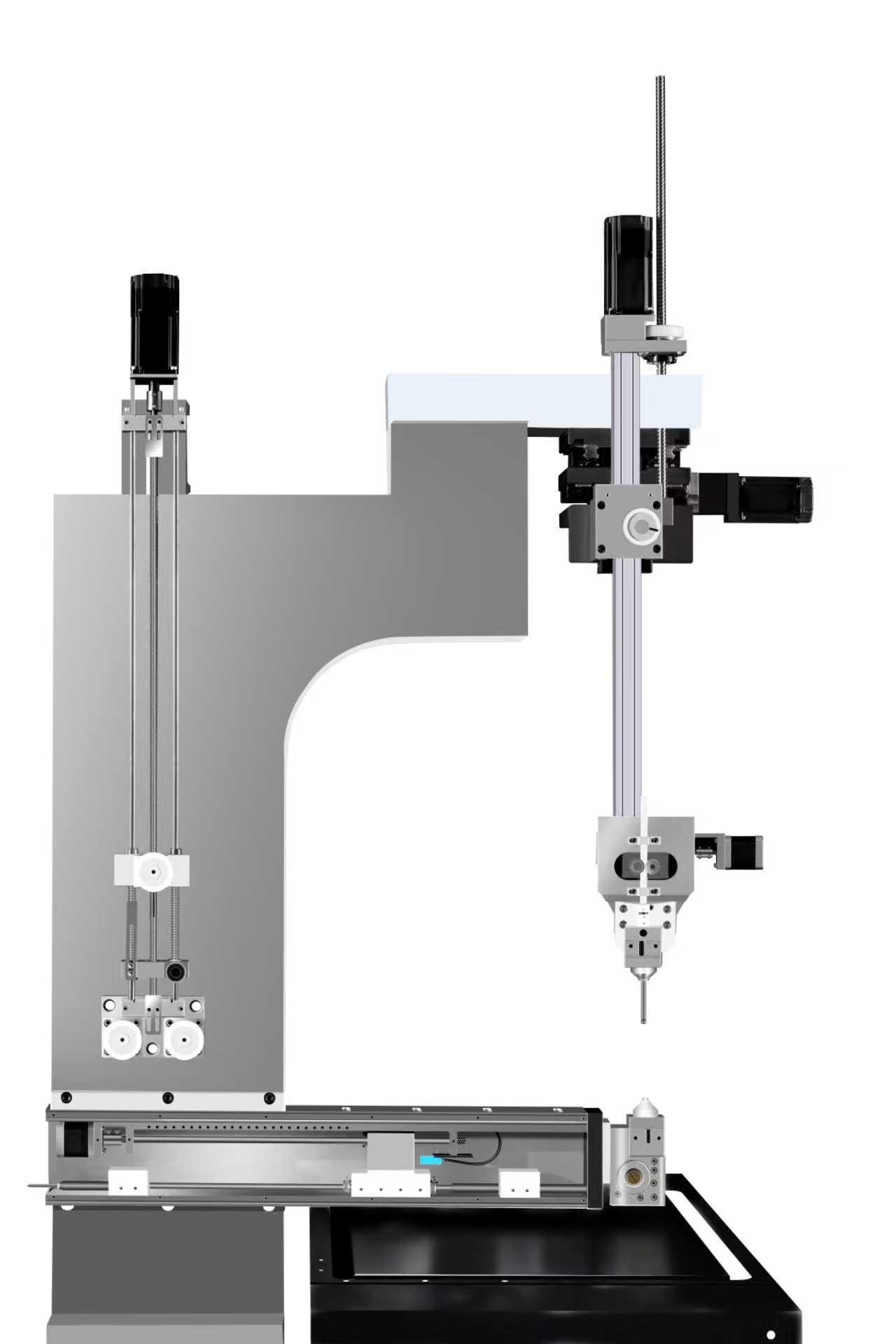

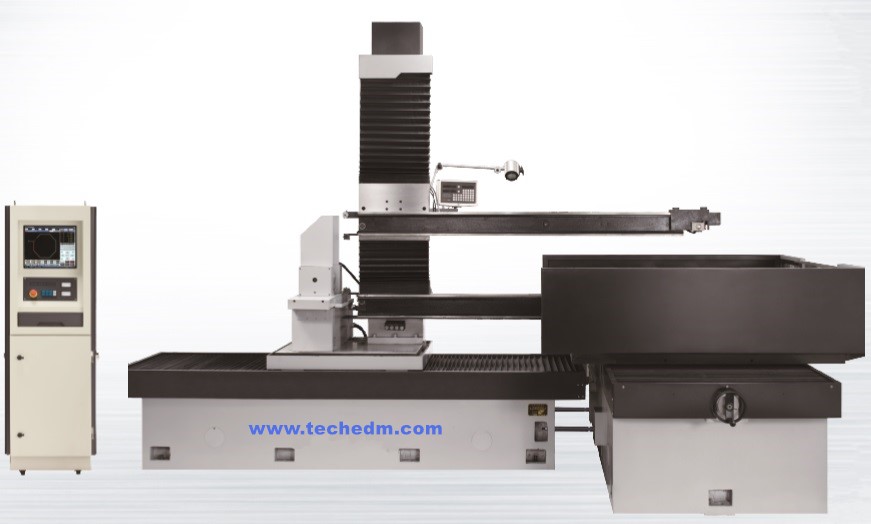

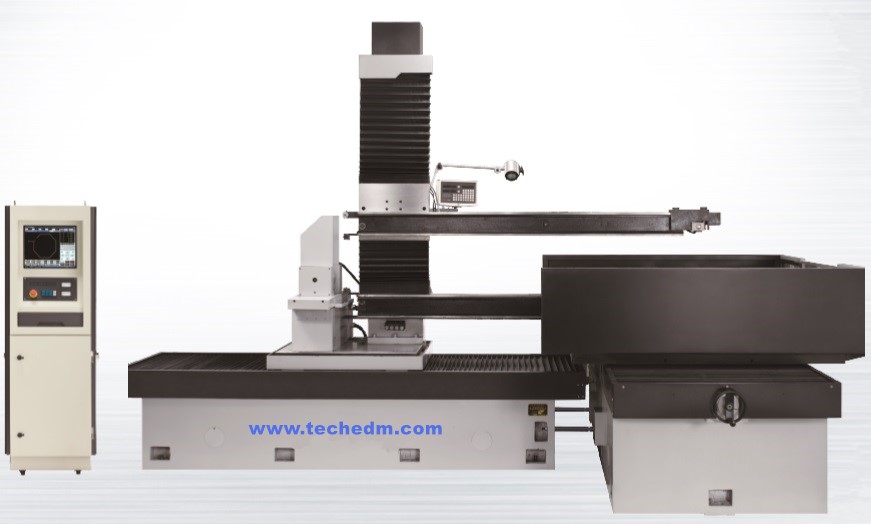

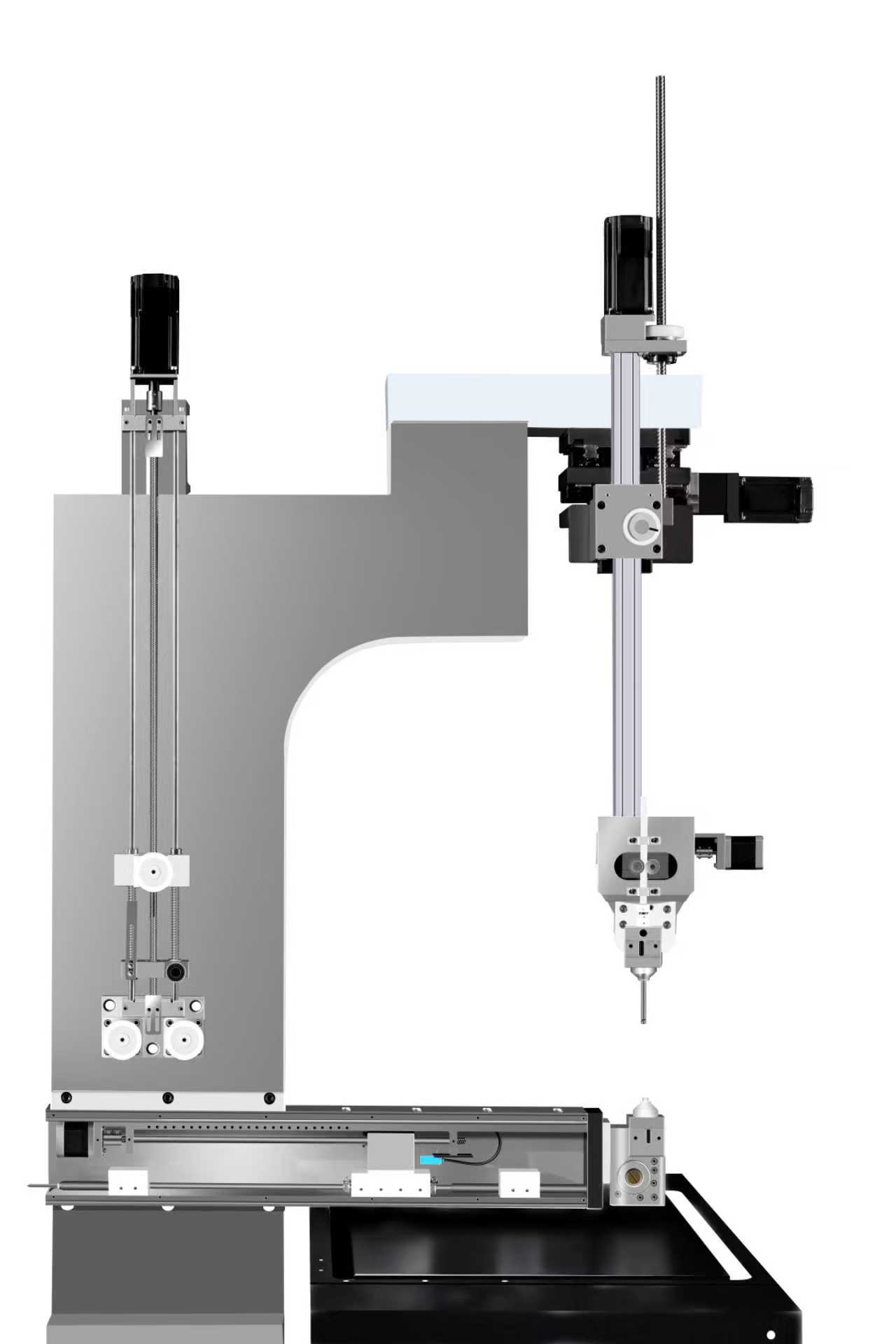

New Designed WEDM with Auto Wire Threading

I. I. Benefits of the latest wire cut EDM machine:

1. Operators friendly: As it is equipped with Auto Wire threading and servo wire tensioning system, and the successful rate of auto wire threading is more than 96%;

2. Excellent cutting accuracy: ≤±0.005, as it is equipped with fully close loop control (7 Axis AC servo motors);

3. Higher cutting speed:>200mm2/min and better roughness: ≤0.8um, as it is equipped with Nanosecond High frequency power.

II. II. Features and advantages:

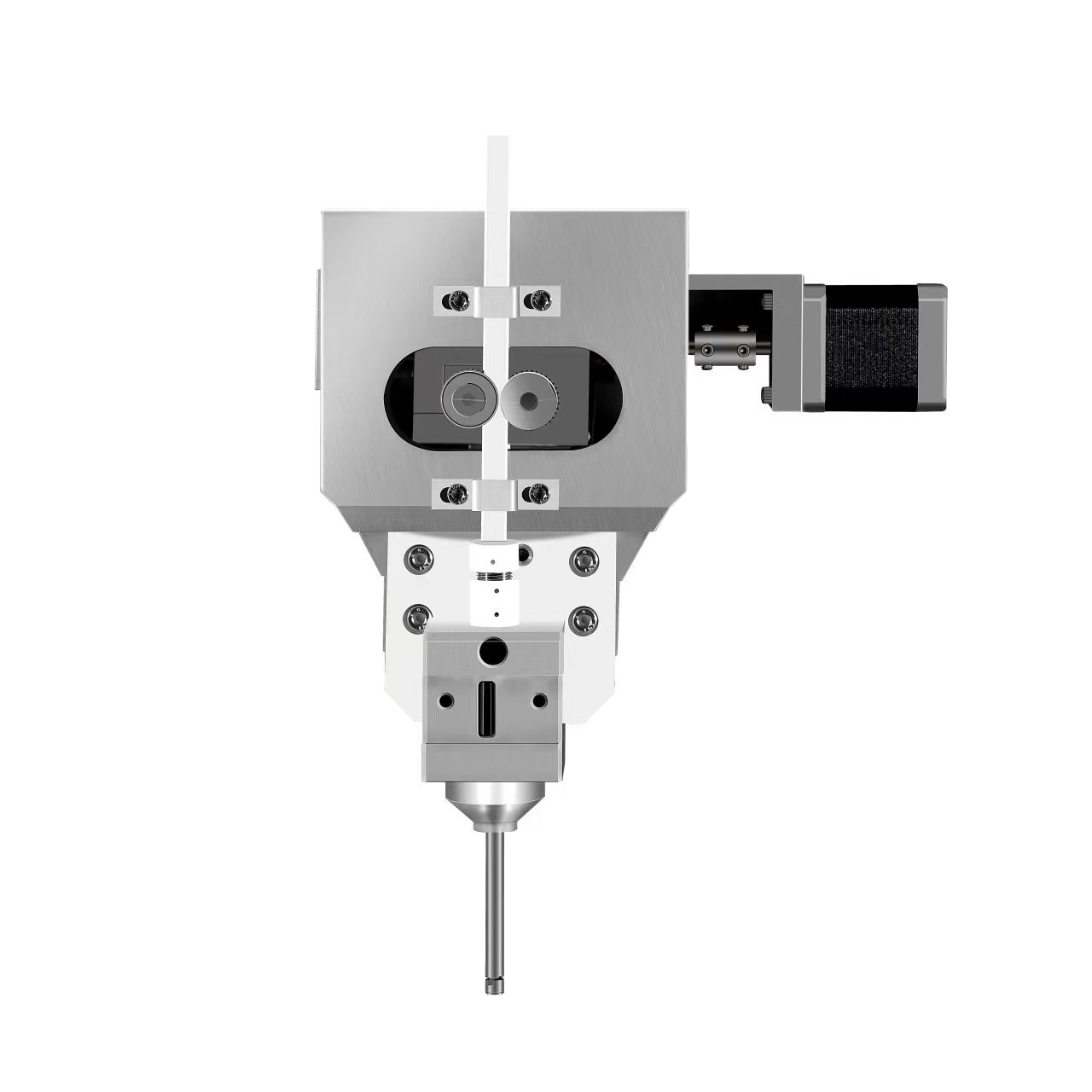

1. Auto wire threading system:

(1) Extremely simple auto threading structure with a higher successful rate of more than 96%;

(2) Both manual and auto threading ways are available;

(3) It is suitable for various working conditions, such as curved workpieces, hollow workpieces, narrow gap workpieces etc.

(4) Batch setting of the threading height or Automatic Z axis sensing to reduce the programming complexity;

(5) Multiple strategies are available for chip free processing and batch centralized waste collection;

(6) In case Auto wire threading fails, various response strategies are available, such as pausing with alarm directly, automatic hole skipping marking, and retry threading standard holes.

2. Full closed loop control system:

(1) The full closed loop control system uses an optical grating ruler to achieve micron level positioning accuracy.

(2) Supports external devices such as laser interferometers for secondary compensation of the machinery tool, to improve the positioning accuracy, re-positioning accuracy and reverse deviation.

3. Nanosecond high-frequency system

(1) The pulse power supply uses a high-speed DSP + FPGA control structure.

(2) Precision control of each discharging pulse.

(3) Pulse-by-pulse sampling for precise sensing of the machining status, with feedback for servo control.

4. Efficient CAM and NC software with minimal operation

(1) Powerful and user-friendly programming system

Quickly select whether to pause before or after the step and pause before step cutting

Supports optional corner clearing function

Supports taper, upper and lower irregular shapes and variable taper cutting.

Supports chip free cutting, which means automatic stepping without generating waste material, with adjustable step length.

Supports auto wire threading function, with adjustable parameters such as threading height.

When there are multiple times cutting paths, the rough cutting can be done firstly, followed by tool finishing. After the first rough cutting and the waste material removing, then the finish cutting can be done finally.

The built- in taper calculator function allows for the adjustment of the taper parameters based on the sample cutting.

The built- in function generates various types of curves, such as the Archimedean spiral.

(2) Intelligent assistance

Supports functions such as offset, material pickup, centering, edge detection, and circle center finding.

Built -in quick templates for rapidly generating straight lines, rectangles, circles, and serpentine curves.

Supports AR correction function: by selecting two points on an edge, the processing path can be corrected automatically.

Supports the function of array processing paths.

Supports the function of selecting multiple paths, automatically sorting them, and generating processing tasks.

(3) Extremely simple software control

Supports functions, such as single step movement, continuous movement, and reverse machining.

Support the function of adding and deleting pause points using the mouse on the UI interface.

Supports the function of modifying parameters for multiple paths with a single click.

Supports the function of setting different processing parameters for each path.

Supports the function of modifying electrical machining parameters at any time.

Supports the function of simulating machining.

Supports the function of alarming in case of errors.

Supports the function of displaying absolute coordinates while allowing the setting of up to 10 independent sets of relative coordinates.

Supports the Auto wire threading function with the ability to modify threading parameters and track data related to automatic threading.

(4) Remote status monitoring

Available on multiple platforms: mini program, app, and desktop client.

Remote control anytime, anywhere.

Numbering the machines.

Display processing time.

Display processing efficiency.

Display processing speed.

Display processing progress.

Display current processing status.

The software can be expanded based on the number of the machines.

I.

I. I III. Specification

I.

|

Parameters |

Specification |

Unit |

MU4 |

MU6 |

|

Automatic wire threading |

Threading time |

Second |

<50 |

<50 |

|

Wire remove time |

Second |

<45 |

<45 |

|

|

Tension |

* |

5 adjustable levels |

5 adjustable levels |

|

|

Threading hole diameter |

mm |

0.3-5 |

0.3-5 |

|

|

Threading workpiece thickness |

mm |

0-350 |

0-350 |

|

|

Max workpiece dimension |

L*W*H |

mm |

510*820*500 |

530*1020*500 |

|

Travel/space |

X/Y/Z axis travel |

mm |

320*400*400 |

400*600*400 |

|

U/V axis travel |

mm |

60*60 |

60*60 |

|

|

Wire diameter |

Moly wire |

mm |

0.1-0.22 |

0.1-0.22 |

|

Max worktable load |

Weight |

Kg |

450 |

800 |

|

Machine dimension |

L*W*H |

mm |

1500*1750*2400 |

1650*1750*2400 |

|

Total weight |

Gross |

Kg |

2000 |

2600 |

|

Machine Total Power |

* |

KW |

1.5 |

1.5 |

|

Taper angle |

R |

°/mm |

±6°/80 |

±6°/80 |

|

Position accuracy |

Position |

mm |

≤±0.003 |

≤±0.003 |

|

Repetitive position accuracy |

Repeated |

mm |

≤±0.001 |

≤±0.001 |

|

Multi cut accuracy |

20*20 Gr12, S=40 |

mm |

≤±0.005 |

≤±0.005 |

|

Surface Roughness |

Ra(Once cutting) |

um |

≤2.5 |

≤2.5 |

|

Ra(Multi- cutting) |

um |

≤0.8(GR12, S=40) |

≤0.8(GR12, S=40) |

|

|

Full axis indexing accuracy |

* |

* |

0.012 |

0.015 |

|

Cutting speed |

* |

* |

>200 |

>200 |

|

Working fluid tank |

Size |

mm |

480*690*600 |

480*690*600 |

|

4 stage filtration accuracy 10 |

um |

10 |

10 |

|

|

NC system |

Control model |

Fully closed loop system |

||

|

Coordinate display |

* |

Absolute/relative coordinates Auto return to Zero |

||

|

Control system |

* |

P cut |

||

|

Intelligent database |

* |

With database |

||

|

File forma |

* |

DXF, DAT, DWG… |

||

|

Communication model |

* |

USB, LAN |

||

|

Guideways |

THK linear guideways for the U/V axis guideways and wire feeding guideway, and Taiwan Dinghan linear guideways for X/Y axis |

|||

|

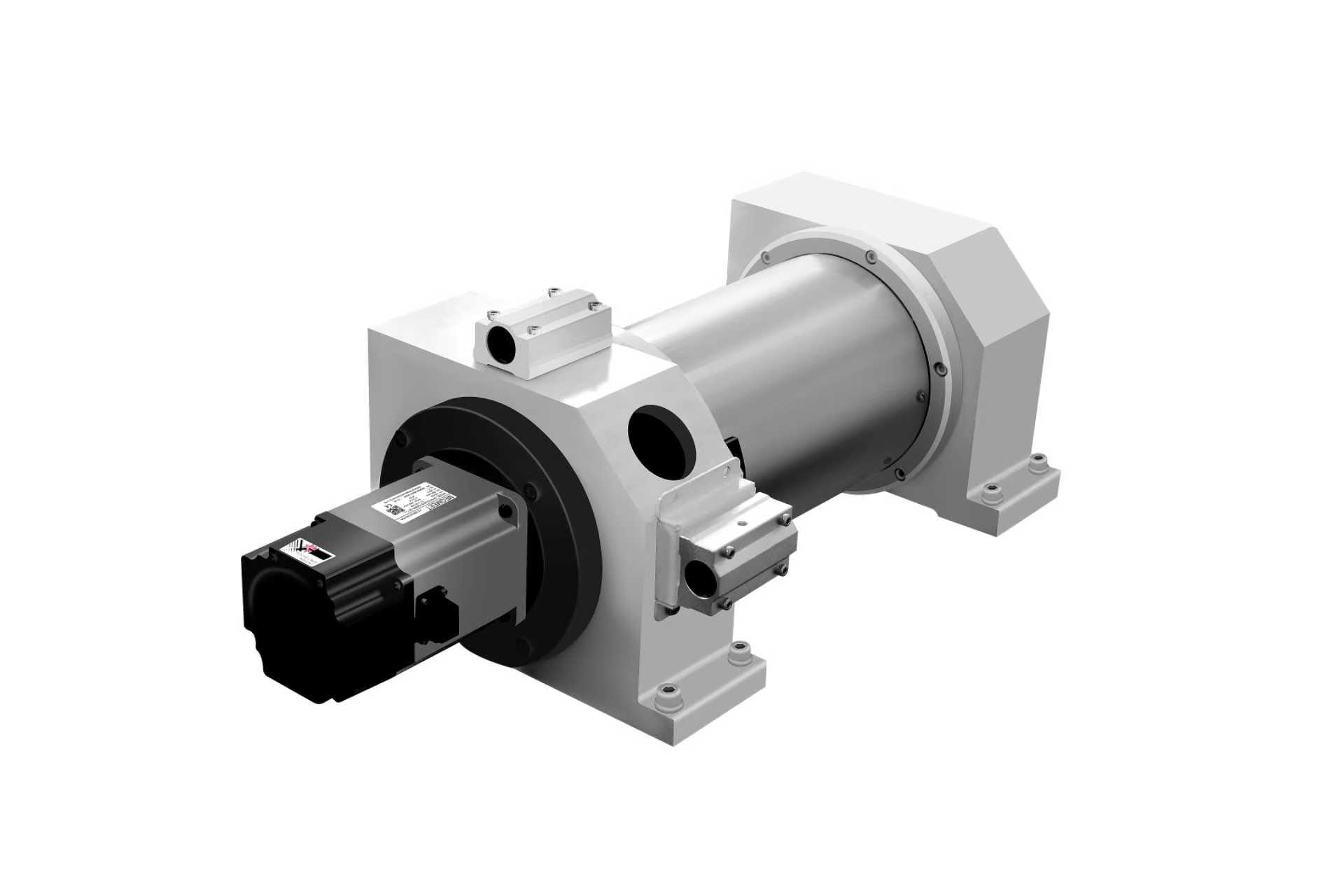

Servo motors |

Multi-turn absolute servo motors with brake |

|||

|

Grating scale |

High precision grating scale with an accuracy:1um, brand: WH or HX |

|||

|

Wire guide |

Industrial gemstones |

|||

|

High-frequency Power supply board |

7-ns narrow-pulse width high -frequency pulse power supply board |

|||

|

Electronic handwheel |

4 axis (X/Y/U/V axis) electronic handwheel |

|||

|

Power supply |

3N-380V/50Hz |

|||

IV. Evidences

1. Jobs of Wire EDM machines

2. Patents of our factory

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap