- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

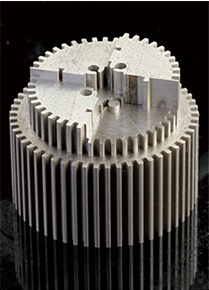

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

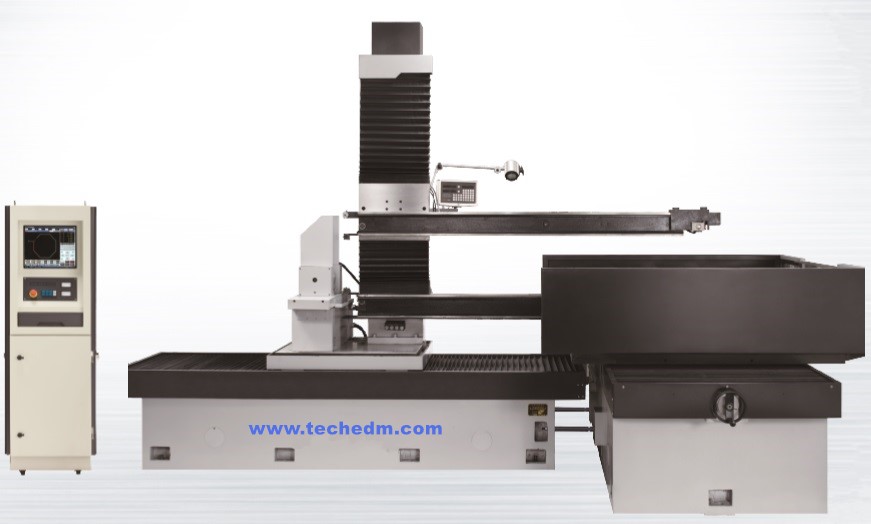

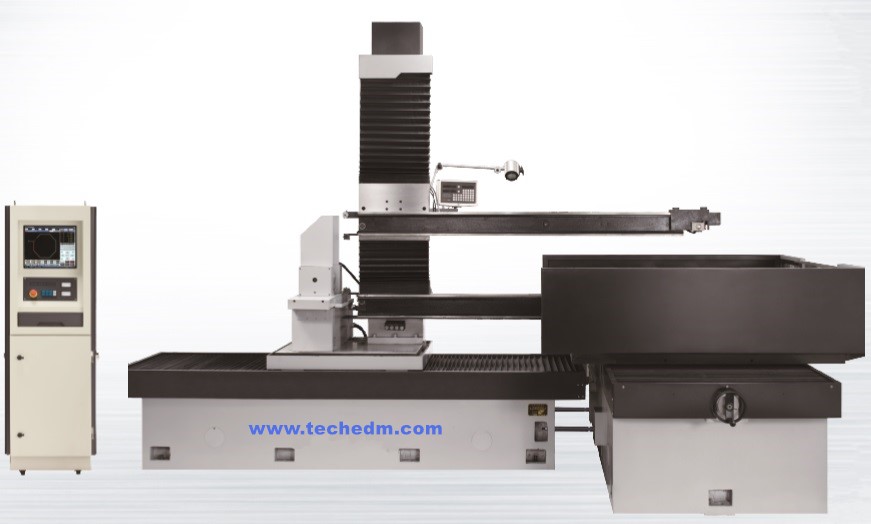

- FRQ about how to choose a suitable wire cut EDM machines

Parameters of

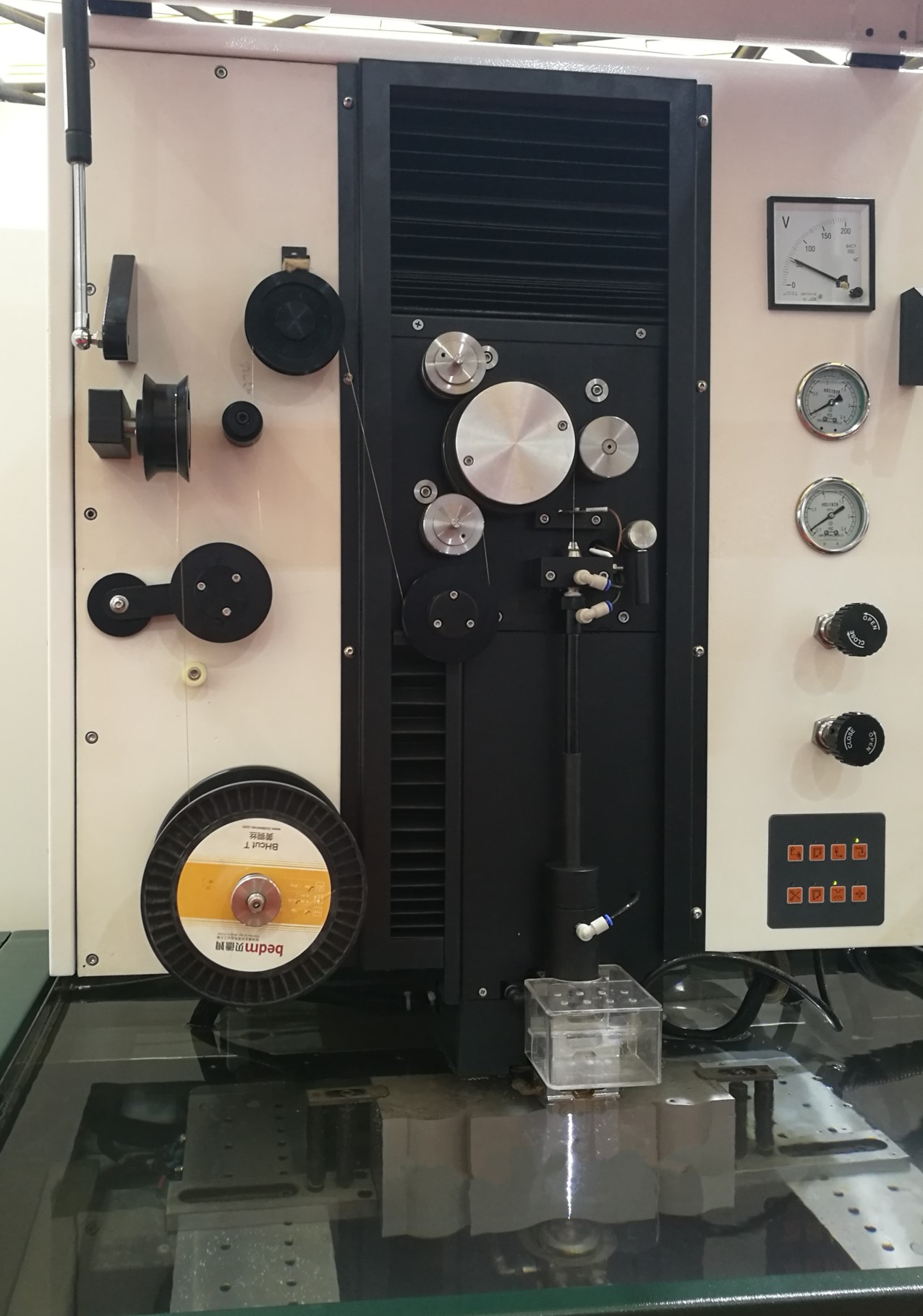

Flushing type wire cut EDM machines

Items

Unit

TF400

TF645

Mechanical body

Travels X/Y/Z

mm

400×300×220

645×450×300

Travels U/V

mm

36×36

100×100

Max.Erosion taper

*

±6°/(100mm thinkness)

±25°/(80mm

thinkness)

Dimension of work-table

mm

645×490

920×690

Max.weight of work-piece

kg

250

600

Max.dimension of work-piece (LxWxH)

mm

850×700×215

1100×850×295

Diameter of electrode wire

mm

0.15-0.30

0.15-0.30

Type of machining

*

Flushing

Flushing

Dimension of the machine

mm

1700×2550×2165

2750×2800×2265

Weight of mechanical body

kg

2500

3800

Floor plan area

(WxH)

mm

2200×3300

2750×2800

Work tank

Dimension of work tank(LxWxH)

mm

990×910×270

1380×1010×370

Filtration

*

Filter paper

Filter paper

ECO-10N

L

Resin(20L)

Coordinate axes

Manual velocity

of axes X/Y/Z

Four grades Max.: 1.2m/min

Double-direction

positioning accuracy A of axes X/Y(according to

ISO230-2:1997)

0.008mm whole

travel

Double-direction

positioning accuracy Aof axes U/V(according to

ISO230-2:1997)

0.012mm whole

travel

Single-direction

repeated positioning accuracy of X/Y axes(R↑ or R↓)

0.004mm

Single-direction

repeated positioning accuracy of U/V axes(R↑ or R↓)

0.006mm

Reverse distance

of B for X/Y

0.004mm

Reverse distance

of B for U/V/Z

0.005mm

Offset for

software pitch offset of X/Y/Z axes

Offset space 5mm

Offset for

software pitch offset of U/V axes

Offset space 1mm

Ball screw of

axes X/Y/Z

Φ25mm/ Bolt

distance 4mm/ Accuracy C3

Slide screw of

axes U/V

Φ8mm/ Bolt

distance 0.8mm

Guide-way of

X/Y/U/V/Z

Linear ball

guide-way

The min.

resolution (X/Y/U/V/Z)

1μm

Deceleration

ratio of the belt of X/Y axes

1:04

Deceleration

ratio of the belt of Z-axis

1:02

Motor of X/Y/Z

AC servo motor

Motor of U/V

Step-motor

Wire-driving system

Diameter of wire

0.15/0.20/0.25/0.30mm

brass wire

Dimension of

wire container

Max.: Φ160mm

Velocity of wire

Max.:200mm/s

Control the

tension of wire when machining

Adjusting

automatically

Wire alignment

Automatically

Wire

installation

Manually

Wire-through

Manually

Wire-retract

Automatically

Dielectric tank

Filtration

One filter paper

(accuracy:5μm, dimension:Φ340x450 direction: from inside to outside)

Cubage of

dielectric tank

300L

Type of medium

Pure water or

distilled water

Capacity of

resin

20L

Water-cooling

system

3500W

Power of

re-cycling pump

0.8Kw

Power of

high-voltage pump

1.5Kw

Power of

water-input pump

0.35Kw

Cabinet

Criterion power

3x380V 50/60Hz

7KVA

Fluctuation

allowed

380V±10% 50±1Hz

Current fully

loaded

10A

CNC

Control system

IPC system

(Celeron 1.66GHz)

Operation system

Windows XP

Hard disk

>80G or CF

card>16G

Type of input

keyboard,USB, LAN

Display

15”LCD

Language

Chinese/English/Portuguese

Controlling axe

Five axes/Four

axes simultaneity

Command mode

Incremental/absolute

Unit

Inch/metric

Interpolation

Linear / arc

Mini. Input

0.001mm

Max. input

999.999mm

The smallest

increment

0.001mm

Coordinate

system

Mechanical, 6

users’ coordinate system

Offset for pitch

error

5 axes

Assistance

function

Suggestive

operation/maintenance

Format of code

ISO

Sub-program

The most layer:

9 the most nesting: 999

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap