- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

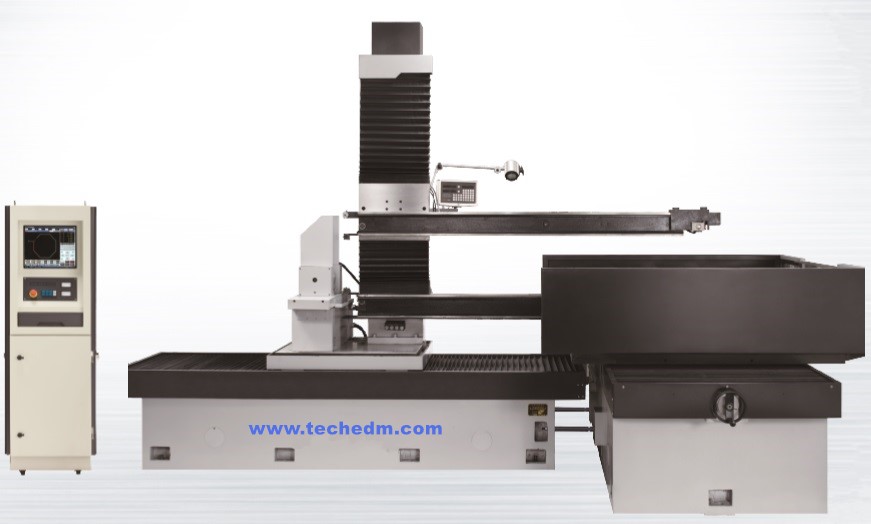

Economical CNC wire cutting EDM machines

I. The benefits you can get with our Economical CNC wire cutting EDM machines:

1. You can save 30%-40% investing cost with our wire cut EDM machine, comparing to our competitors in the market.

2. You can master the operation software in 1-2 hours. It is a user friendly wire cutting software running on Windows XP computer.

3. You can be rest assured about its performance in the following years.

II. Advantages of our Economical CNC wire cutting EDM machines:

1. Longer working life;

2. Lower failure;

3. Easier operation.

III. Main parameters of the CNC wire cutting EDM machines:

Specification

TE35

TE45

TE55

TE63

TE80

Travel

X/Y axis travel

mm

350*450

450*550

550*800

630*1000

800*1000

Table

size

L*W

mm

360*608

490*790

720*1150

820*1200

980*1980

Max

cutting thickness

H

mm

400

400

500

600

600

Taper

angle

R

degree

±3°/100

Max

cutting speed

*

mm2/min

140

Roughness

Ra(Once cutting)

um

≤2.5

Ra(Multi- cutting)

um

≤1.5

Precision

*

mm

≤0.015

Weight

*

kg

1100

1300

1400

1500

1800

Motor

Step Motors on X/Y axis

Machine

dimension

L*W*H

cm

145*140*170

160*160*170

180*180*180

205*200*180

275*240*200

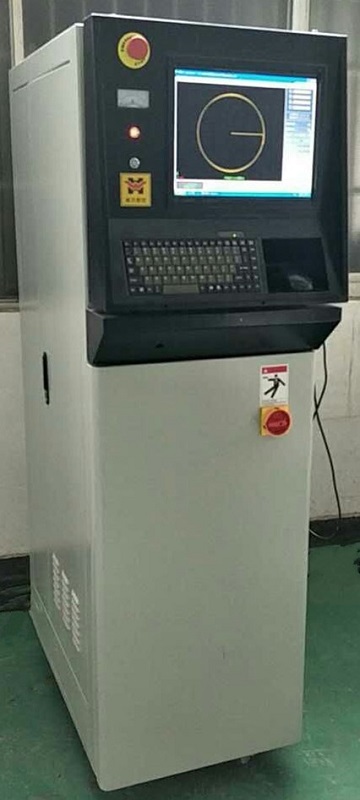

IV. CONTROL SYSTEM Windows XP

1. The controller equipped the auto cut intelligent software, which integrates the program and control and based on Windows XP. This new designed auto cut software is the unique software for WEDM running on the condition of windows XP.

Coordinate system: Absolute coordinate, incremental coordinate (relative coordinate);

|

(1)Coordinate system: Absolute coordinate, incremental coordinate (relative coordinate) |

||||

|

(2) Functions of coordinate transforming, zooming in and zooming out, rotating and tracking display in real time |

||||

|

(3)Functions of interpolation of straight line and circular arc |

||||

|

(4)Function of taper processing: As above |

||||

|

(5)Function of processing different top and bottom abnormities parts |

||||

|

(6)Auto-handle for short circuit and wire-break |

||||

|

(7)Functions of memorizing: unexpected power off, it can continue the processing automatically; auto-stop after processing |

||||

|

(8)Functions of auto edge-touching position and auto center finding |

||||

|

(9)Function of auto-adding transitional arc (Arbitrary angle) |

||||

|

(10) Functions of menu technology and auto-programming ward |

||||

|

(11)Functions of menu technology and auto-programming |

||||

|

(12)AUTOCAD can be used to program directly in the software.

|

||||

|

2. Using the PCI slot controller card, LCD Monitor and the High-tech Industrial computer. That greatly enhances the stability of control and greatly reduces the computer the failure rate.

|

||||

|

3. Embedded Control system can be connected with many design software smoothly.

|

||||

|

4. Variety of pulse power can be chosen, which is suited for a number of processing conditions to improve the cutting ability of the high precision parts.

|

||||

|

5. With a large database storage capacity, user can choose the suitable parameter according to deferent working conditions. Users can adjust machining parameters to establish a database at any time according to their own experience

V. CNC system configuration and technical performances.

|

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap