- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

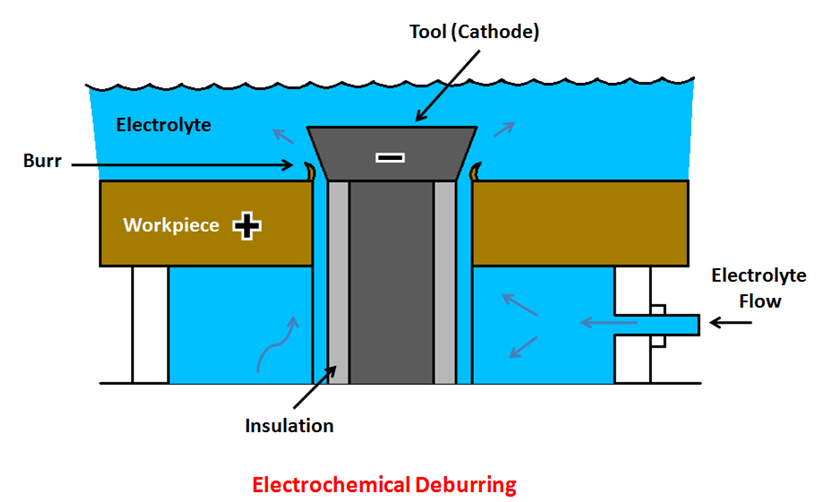

Chemical deburring, often referred to as electrochemical deburring (ECD), is an advanced technique used to remove burrs and sharp edges from metal parts through an electrochemical reaction. This method is particularly effective for complex, intricate, or hard-to-reach areas (like inner holes or intersections), where traditional mechanical deburring might be difficult or impractical.

Working Principle of Electrochemical Deburring (ECD)

The basic principle of electrochemical deburring is the controlled removal of material from a workpiece by an electrochemical reaction, where the burrs or sharp edges are selectively removed through anodic dissolution (i.e., the process where metal is oxidized and dissolved into a solution). The key components involved are:

- Anode (Workpiece): The metal part (typically the workpiece containing burrs or sharp edges) serves as the anode in the electrochemical process. The burrs or excess material are located at specific areas of the workpiece, like sharp edges, holes, or intersections.

- Cathode (Electrode): A specially designed cathode (usually a conductive tool or electrode) is placed near the workpiece. The cathode is often shaped to match the geometry of the part, especially around difficult-to-reach areas like internal or crossing holes. The cathode is connected to the negative terminal of the power supply.

- Electrolyte Solution: The electrochemical deburring process occurs in an electrolyte bath, which is typically an aqueous solution of acids or salts (e.g., sodium nitrate or sulfuric acid). The electrolyte acts as a medium to facilitate the movement of ions and the electrochemical reactions.

- Power Supply: A direct current (DC) power supply is used to create a potential difference between the anode (the workpiece) and the cathode (electrode). The voltage applied is usually low (typically 10 to 30 volts, depending on the material and size of the part).

Process Overview:

- Electrochemical Reaction:

- When a DC voltage is applied between the workpiece (anode) and the cathode, an electric current flows through the electrolyte solution.

- The part's burrs or sharp edges, being at the highest points on the surface, become anodic (positively charged).

- The metal in these areas undergoes oxidation, turning into metal ions and dissolving into the electrolyte solution. This occurs preferentially on the burrs or sharp edges because they have a higher surface energy and thus experience a greater electrical potential.

- Material Removal:

- As the burrs dissolve, the material is gradually removed from the workpiece, leaving the remaining surfaces smooth and free of sharp edges.

- The removal rate is selective, meaning the process predominantly affects the high points (burrs) and not the rest of the workpiece, allowing the core material to remain intact.

- The material is removed in a controlled manner, and the process can be tailored to remove only the burrs without significantly affecting the part's overall geometry.

- Deburred Surface:

- After a sufficient amount of time has passed, the burrs are eliminated, and the remaining surface becomes smooth.

- The process can be stopped at any time, depending on the desired surface finish and the extent of burr removal.

Key Features of Electrochemical Deburring:

- Precision: ECD can precisely remove burrs without affecting the overall geometry or dimensions of the part. It’s especially useful for intricate or hard-to-reach areas (like inner holes or corners).

- Selective Material Removal: The process is highly selective, meaning it targets only the burrs and sharp edges, leaving the rest of the workpiece unaffected.

- No Mechanical Force: Since the deburring is done through a chemical reaction and not mechanical abrasion, there is minimal risk of damaging delicate features or introducing additional stresses into the material.

- Minimal Heat Affected Zone: Unlike other thermal processes (such as laser or flame deburring), electrochemical deburring generates very little heat, reducing the risk of thermal distortion or damage.

- No Tool Wear: Because there is no physical contact between the workpiece and the tool, the process does not cause tool wear, which is common in mechanical deburring methods.

Steps Involved in the Electrochemical Deburring Process:

- Preparation: The workpiece is placed into a fixture or holder, ensuring that it remains in a fixed position during the deburring process. The part is connected to the anode (positive terminal) of a DC power supply.

- Electrode Setup: The cathode (electrode) is shaped to match the geometry of the workpiece, especially the internal holes or areas to be deburred. The electrode is connected to the negative terminal of the DC power supply.

- Electrolyte Bath: The workpiece is submerged in an electrolyte bath, which serves as the medium for the electrochemical reaction. The electrolyte is carefully chosen based on the material of the workpiece and the desired deburring effect.

- Applying Current: Once the workpiece and electrode are in place and the electrolyte is flowing, a controlled DC current is applied. The electrochemical process begins, and the burrs are selectively dissolved away.

- Monitoring and Control: The process is typically monitored using sensors or visual inspections to ensure that the burr removal is occurring at the right rate. The time and current are carefully controlled to avoid over-deburring or damaging the part.

- Post-Deburring Cleaning: After the deburring process, the workpiece is removed from the electrolyte bath, cleaned to remove any residual electrolyte, and inspected for burr removal quality.

Advantages of Electrochemical Deburring:

- Effective for Complex Geometries: ECD is particularly suited for deburring intricate shapes, internal cavities, and intersecting holes that are difficult to reach using traditional methods.

- No Physical Contact: There is no mechanical wear or contact, reducing the risk of surface damage, distortion, or work-hardened surfaces.

- High Precision: The process can achieve high precision in deburring without altering the rest of the workpiece's geometry.

- Fast Process: It can quickly deburr parts, especially when compared to manual methods or traditional mechanical processes.

Disadvantages:

- Setup Cost and Complexity: The equipment for electrochemical deburring can be expensive and requires skilled operators. The electrolyte bath must also be carefully maintained.

- Material Limitations: The process is more effective on conductive metals (like stainless steel, titanium, aluminum, copper, etc.) and may not be suitable for non-metallic materials or non-conductive metals.

- Environmental Concerns: The electrolyte solutions used in ECD can be hazardous and require proper disposal or recycling to avoid environmental contamination.

In summary, electrochemical deburring is a precise, efficient method for removing burrs from metal parts, especially in complex geometries or hard-to-reach areas. It uses an electrochemical reaction to selectively remove material from burrs, leaving the rest of the part's surface intact.

For more information about ECM machines, please feel free to contact us.

Bob Li

Mobile(Whats app): +86-13338697597

Tech EDM Trade Co., Ltd

Tel: +86-512-68782578

Fax:+86-512-66671799

Email: sale@techedm.com

Email: edmachining@hotmail.com

Add: No. 58 Huajin Rd, 215153, Suzhou, China

www.techedm.com

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2024-11-11

2024-11-11