- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

- FRQ about how to choose a suitable wire cut EDM machines

The advantages of graphite electrodes in EDM application.

1: The increasing complexity of the mold geometry and the diversification of product applications lead to more and more accurate sinker EDM machines. Graphite electrode has the advantages of easy processing, high removal rate of discharge machining, small graphite loss, and therefore, some of the group of spark machine customers to give up the copper electrode and choose the graphite electrode. Also some special shape electrode cannot be made of copper, but graphite is easy molding and copper electrode is heavy, not suitable for the processing of large electrode, these factors caused partial group base spark machine customers by graphite electrode.

2: Graphite electrode is easier to process, and the processing speed is much faster than the copper electrode. For example, the milling process of graphite, the processing speed of the graphite is 2 to 3 times faster than other metal processing and no need for additional manual processing, and the copper electrode is required manpower grinding. Similarly, if the use of high speed graphite processing center for manufacturing graphite electrode, the speed will be faster, more efficient, but also will not produce dust problems. In these processes, the choice of appropriate tools and hardness of graphite can reduce the wear and tear of the tool and the damage of copper. If the milling time of the graphite electrode and the copper electrode graphite electrode are compared, the graphite is 67% faster than that of the copper electrode. In general, the machining of the graphite electrode is 58% faster than that of the copper electrode. In this way, the processing time is greatly reduced, but also reduces the cost of manufacturing.

3: The design of the graphite electrode is different from that of the traditional copper electrode. Many mold factories usually in copper electrode of rough machining and finish machining with different amount of reserve, and graphite electrode is used almost the same amount of reserved. This reduces the number of CAD /CAMand machine processing, for this reason alone is sufficient to improve the accuracy of the mold cavity in a large extent.

How to use graphite materials and other relevant factors to consider is, of course, mould factory by the copper electrode conversion of graphite electrode. First of all, should be clear. Today, part of the group of spark machine customers using graphite electrode discharge machining, which eliminates the mold cavity polishing and chemical polishing process is still able to achieve the desired surface finish. Without increasing the time and polishing process, the copper electrode can not produce such a workpiece. In addition, graphite is divided into different levels; in a specific application using the appropriate levels of graphite and electric spark discharge parameters to achieve the ideal processing effect, if the graphite electrode spark machine uses the operating personnel and the copper electrode of the same parameters, then the result would is disappointing. If the material of the electrode is strictly controlled, the graphite electrode can be arranged in the non loss state (less than 1%) in the rough machining, but the copper electrode is not used.

Graphite has the following copper can not match the quality characteristics:

Processing speed: high speed milling and rough machining is 3 times more than that of copper; high speed milling process is 5 times more than that of copper.

Machinability is good, can achieve complex geometric modeling

Light weight, less density of copper 1/4, electrode holder

Can reduce the number of individual electrodes, because they can be bundled into a combination of electrodes

Good thermal stability, no deformation and no burr.

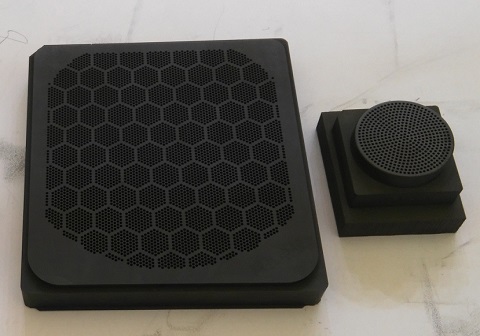

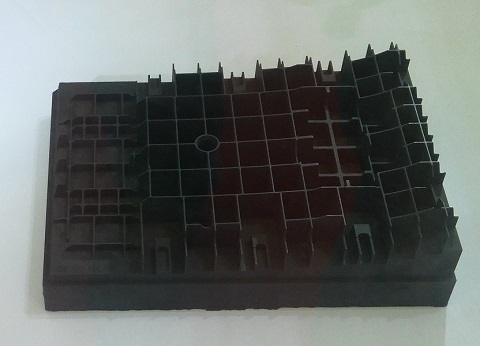

Here are some pictures of the graphite electrodes as following:

- Opening of the 9th CCMT

- The advantages of graphite electrodes in EDM applications

- IMTS2016 will be held in Chicago in Sept12-17,2016

- What is the Cold Draw Tubing Dimensional Tolerance?

- How to solve the worse surface on WEDM?

- The possible reasons and solutions of the wire-breaking matters on the low running speed WEDM.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2016-8-5

2016-8-5