- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

How to select the grinders between Vertical Spindle Rotary Table Grinders and Horizontal Spindle Rotary Table Grinders?

What are the Key Differences Between Vertical Spindle Rotary Table Grinders and Horizontal Spindle Rotary Table Grinders for Machine Model Selection?

This comparison highlights the core distinctions to help you choose the most suitable grinding machine for your application.

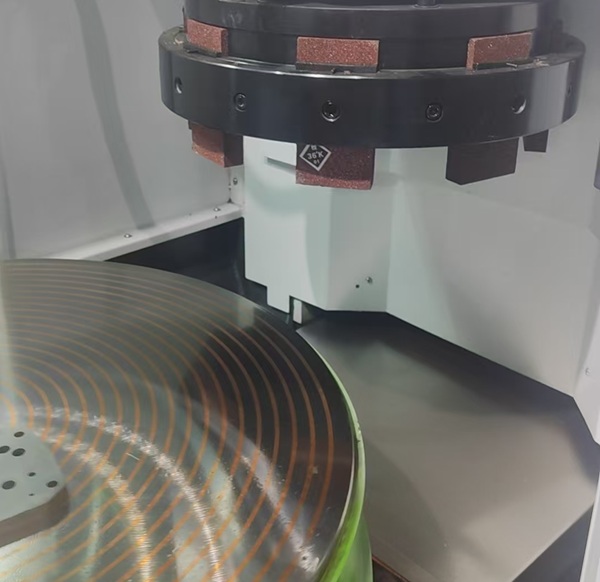

Vertical Spindle Rotary Table Grinder

• Principle:

The grinding spindle is perpendicular to the worktable (vertical), using the face of the grinding wheel. The worktable rotates horizontally.

• Key Characteristics:Large Contact Area: The entire wheel face contacts the workpiece, enabling a very high metal removal rate and exceptional productivity.

High Rigidity: Robust spindle structure withstands heavy grinding forces.

Primary Focus: Efficiency and stock removal for achieving flatness.

Typical Tolerance & Finish: Generally suited for lower surface roughness and dimensional precision compared to horizontal spindle types of the same class.

• Primary Applications:

1. Roughing/Semi-finishing of large surfaces in mass production (e.g., engine blocks, transmission cases, machine bed castings).

2. High-efficiency grinding of difficult-to-machine materials (e.g., titanium alloys, aerospace components).

3. Mold industry: Stock removal and surface grinding for large mold bases.

4. Form grinding and slicing of non-metallic hard/brittle materials like magnetic materials or ceramics.

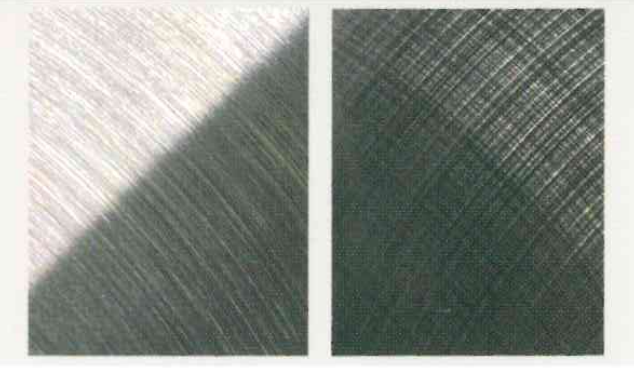

Horizontal Spindle Rotary Table Grinder

• Key Characteristics:

Small Contact Area: The wheel contacts the workpiece with its high-speed periphery, resulting in low grinding force and minimal heat generation.

Superior Accuracy: Stable process delivers extremely high flatness, parallelism, and very low surface roughness.

Effective Cooling & Chip Removal: Open grinding zone allows optimal coolant flow and chip evacuation.

Primary Focus: Ultimate precision and fine surface finish.

Efficiency: Lower stock removal per pass, best for finishing.

1. Precision & ultra-precision finishing of components like hydraulic parts (pump/valve faces), precision bearing rings, gauges, piston rings.

2. Thin-part grinding: Low grinding force minimizes distortion, ideal for shims, friction discs, saw blades.

3. Tool industry: Precision surface grinding of carbide/ceramic inserts.

4. Semiconductor & optics: Precision lapping/grinding of silicon wafers, optical glass, crystals (often with specialized wheels).

For more information about these two models of grinding machines, please feel free to contact us.

Mobile(Whats app): +86-13338697597

Tech EDM Trade Co., Ltd

Tel: +86-512-68782578

Fax:+86-512-66671799

Email: sale@techedm.com

Email: edmachining@hotmail.com

Add: No. 58 Huajin Rd, 215153, Suzhou, China

www.techedm.com

- The advantages of graphite electrodes in EDM applications

- The possible reasons and solutions of the wire-breaking matters on the low running speed WEDM.

- Why the EDM wire breaks frequently during edge-finding on wire EDM machines?

- Our Electrical Discharging Saw(EDS) Workshop was visited by Indian Clients

- Two Sets small hole EDM machines were shipped to European market

- Electrical Discharge Saw(EDS) Used for ESR Ingots Cutting at a Super Fast Speed.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2025-12-25

2025-12-25