- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

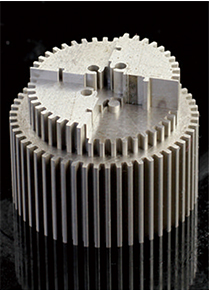

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

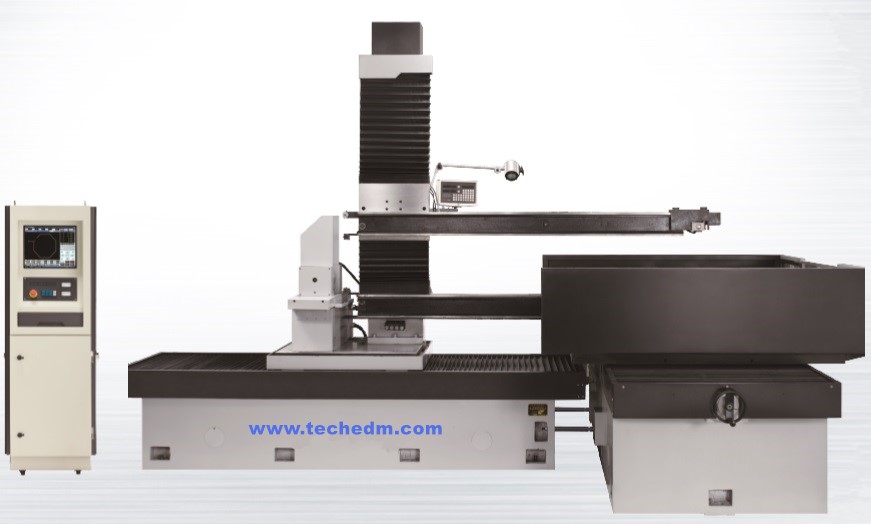

- FRQ about how to choose a suitable wire cut EDM machines

|

Parameters of Wire EDM machines |

||||||

|

Specification |

TB360 |

TB360T |

TB500 |

TB500T |

||

|

Travel |

X axis travel |

mm |

360 |

360 |

500 |

500 |

|

Y axis travel |

mm |

250 |

250 |

350 |

350 |

|

|

Z axis travel |

mm |

210 |

210 |

300 |

300 |

|

|

U/V axis travel |

mm |

100*100 |

90*90 |

100*100 |

90*90 |

|

|

Max taper |

Taper/Height |

°/mm |

±30/50 |

|||

|

Coolant way |

|

|

Submersed/flushed |

|||

|

Wire diameter range |

Min ~ Max |

mm |

0.15-0.3 |

|||

|

Wire tension |

* |

N |

Automatic constant tension |

|||

|

Wire speed |

* |

mm |

30-200 |

|||

|

Max wire spool size |

Diameter |

mm |

160 |

|||

|

Threading device |

* |

* |

Semi-auto |

Auto |

Semi-auto |

Auto |

|

Work tank dimensions |

L*W *H |

mm |

910*680*260 |

1120*800*350 |

||

|

Max workpiece dimensions |

L*W *H |

mm |

900*600*210 |

1000*600*295 |

||

|

Max workpiece Weight |

|

Kg |

400 |

400 |

||

|

Table size |

L*W |

mm |

650*485 |

800*585 |

||

|

Generator |

||||||

|

Max cutting speed |

* |

mm2/min |

160(250 Optional) |

|||

|

Best roughness |

* |

um |

≤0.4(0.25 Optional) |

|||

|

Work type |

AC MOSFET selectrodless generator |

|||||

|

Standard technics |

Steel, carbide, copper, graphite |

|||||

|

CNC control system |

||||||

|

Control system |

1.66GHz CPU |

|||||

|

Operation system |

Windows XP |

|||||

|

Hardware configuration |

16G CF card, 2 G BRAM, 17' LCD |

|||||

|

Input/output interface |

Keyboard, USB, local area network |

|||||

|

Axes controlled |

XYZUV axis( 4 axis controlled simultaneously) |

|||||

|

Memory function |

With menory function |

|||||

|

Power supply system |

||||||

|

Standard supply system |

380V-50Hz |

|||||

|

Power input |

* |

KVA |

7 |

|||

|

Environment requirements |

||||||

|

Clean air, and without direct sunlight. |

||||||

|

The indoor is without the dust source of grinding machine, chemical corrosion gas and vibration. |

||||||

|

Avoid the high dampness, the best is 40-80% |

||||||

|

The temperature requirements:insure accuracy20°C±1°C;insure working 15-30°C |

||||||

|

Machine Dimensions |

L*W *H |

cm |

270*230*225 |

285*240*225 |

||

|

Machine Weight |

G |

Kg |

3000 |

3550 |

||

1. Features:

1. ) Function of Wire broken solution:

2. )Function of power off memory

3. )Function of short circle solution

4.) Function of power adjusting

5. )Function of limits protecting

2. Software system

1. ) It is compatible with AutoCAD

2005-2013 ( DWG files )

2.) Auto programming. The NC programming

can be created according to the material, thickness, cutting path, cutting

times, cutting types etc.

3.) Distance control. The user can control

the working condition by Team viewer.

4.) Function of corner controlling.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap