- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

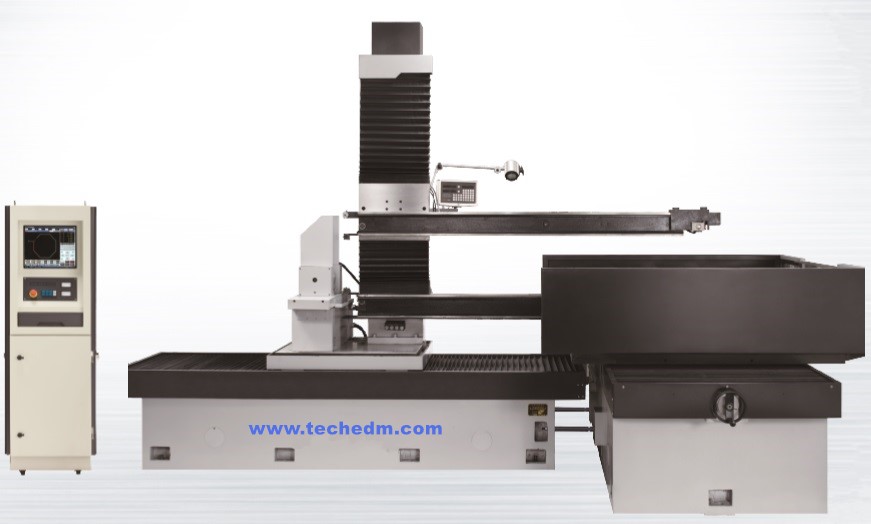

1. Technical specification

|

Mechanical body |

|

|

Dimension of the machine |

2040x1600x1830mm |

|

Weight of mechanical body |

2000kg |

|

Dimension of work-table |

590x440mm |

|

Distance between work-table and floor |

900mm |

|

Travel X/Y |

400x300mm |

|

Travel Z |

250mm (manually) |

|

Working tank |

|

|

Dimension of work tank |

960x550mm |

|

Work piece |

|

|

Maximum cutter head diameter (mm) |

300mm |

|

Maximum cutter head width (mm) |

0-50(See the optional mandrel part for details) |

|

cutter head Angle range (°) |

Back Angle 0-20, side back Angle 0-15, other angles are not limited, the distance between the two gears at least 15mm |

|

Type of cutting tools |

Wood floor molding Disc cutter、Clasp knife、Woodworking router、Furniture line knife |

|

Coordinates axis |

|

|

Ball screw of axes X/Y |

Φ32mm/ Bolt distance: 4mm |

|

Guide-way of X/Y |

Linear ball guide-way |

|

Motor of X/Y axis |

DC servo motor |

|

Location feedback of X/Y axis |

2500 lines encoder |

|

The smallest differentiation rate of X/Y axis |

0.001mm |

|

Software pitch compensation |

5mm |

|

Universal force (angular deflection mechanism) |

|

|

Model |

TW40R |

|

angular deflection mechanism |

±45° |

|

Maximum deflection Angle of U axis |

±45° |

|

Tool effective deflection Angle |

±15° |

|

U axis(option) |

|

|

Model |

TW40R |

|

Travel U |

36x36 |

|

Maximum deflection Angle of U axis |

±8° |

|

Side rear Angle Angle is recommended |

≦±3° |

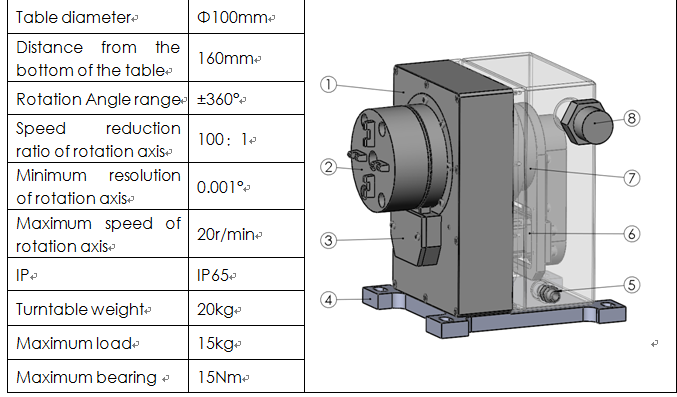

C axis

|

Table diameter |

Φ100mm |

|

Distance from the bottom of the table |

160mm |

|

Rotation Angle range |

±360° |

|

Speed reduction ratio of rotation axis |

100:1 |

|

Minimum resolution of rotation axis |

0.001° |

|

Maximum speed of rotation axis |

20r/min |

|

IP |

IP65 |

|

Turntable weight |

20kg |

|

Maximum load |

15kg |

|

Maximum bearing |

15Nm |

|

Wire-driving structure |

|

|

Motor |

AC velocity-measuring motor |

|

Velocity of wire |

4 grades |

|

Wire-tighten mode |

Automatically |

|

Wire-loading mode |

Automatically/manually |

|

Dimension allowed of wire |

Φ0.12~0.20 Min.:Φ0.07,Max.:Φ0.25 |

|

Tension control of wire |

constant tension |

|

Safety protection |

The handle pops out automatically Wire-break, Wire container stops up, Left and right limit Two times limit |

|

Water tank |

|

|

Dimension of water tank |

900x500x570 (without pump) |

|

Cubage of water tank |

180L |

|

Water tank pump power |

0.37KW |

|

Dimension of filter paper |

φ100x190mm |

|

Accuracy of filter paper |

Normal filter adsorption |

|

Cabinet |

|

|

Standard power |

3x380V 50/60Hz 2KVA |

|

Fluctuation allowed |

380V±10% 50±1Hz |

|

Loaded fully current |

3A |

|

Dimension |

570x694x1830mm |

|

Weight |

250Kg |

|

Filter net |

Stainless steel |

|

CNC |

|

|

Control system |

IPC system and CPU system |

|

Operation system |

Windows XP |

|

Hard disk (SSD) |

>64GB |

|

Display |

15”LCD |

|

Type of input |

MDI,USB,LAN |

|

Format of code |

ISO |

|

Programming |

Automatically/manual,program in machining |

|

Program software |

Novick CAD/CAM |

|

Keyboard |

Standard keyboard |

|

Standard mouse |

Standard mouse |

|

Language |

Chinese /English |

|

Controlling axes |

Four axes simultaneity |

|

Command mode |

Incremental/absolute |

|

Unit |

Inch/metric |

|

Interpolation |

Linear / arc |

|

Mini. Input |

0.001mm |

|

Max. input |

9999.999mm |

|

The smallest increment |

0.001mm |

|

Coordinates system |

Mechanical and customer |

|

Coordinates of offset for pitch error |

4 axes |

|

Assistance function |

Suggestive errors |

|

Sub-program |

The most layer: 9 the most nesting: 99 |

|

Prepare functions |

Center-finding /wire alignment/ edge-finding /set and return to reference /mechanical reference |

|

Programming |

Mirror image of axe X/Y, exchange of axes X/Y ,rotation, proportion |

|

Variable of program |

H register |

|

Machining |

Drawing-checking/ Machining-tracking |

|

Edit |

Set new file/Save file/Re-name file/ Delete file |

|

Power-cut automatically |

Save automatically when power-off/ resume automatically when power-on |

|

Remote control |

Have this function |

|

Programming during machining |

Have this function |

|

Multi-time cut machining program automatically |

Have this function |

|

Modify parameters of generator during machining |

Have this function |

|

Diagnosis |

Have this function(just for maintenance personnel) |

|

Error message is displayed in real time. |

Have this function |

|

Machining state is displayed in real time. |

Have this function |

|

Display the edition of software/ hardware |

Have this function |

|

Display date and machining time |

Have this function |

|

Configuration of machine parameters |

Have this function |

|

Remote control |

|

|

Function keys |

Display of axes X/Y/U/V/ Axis selection and movement / moving velocity and single /start pump/wire-driving/ moving velocity and single / start-stop-pause/return to origin / edge-finding-center-finding/set to origin |

|

Generator and machining |

|

|

Max. machining current |

15A |

|

Max. machining velocity |

300 mm2/min |

|

Best roughness |

Ra≤ 0.8μm |

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap