- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

I. Main Specification

Model

TD406CNC

Work table size

550×360mm

Table travel(X×Y*Z)

400×300*370mm

S axis travel

400 mm

B axis rotation Angle

±90°

C axis rotation Angle

0-360°

C axis rotation table diameter

250mm

C axis rotation table load

≤30kg

Max distance between worktable to electrode chuck

400mm

Electrode diameter

0.15-3.0 mm

Electrode chuck

Pneumatic spring chuck

Max moving speed of straight axis

≥2000mm/min

Motors of axis

Japan Panasonic/Fuji AC servo motor (absolute encoder)

Min moving

equivalent

0.001mm

Axis movement control mode

Multifunctional electronic hand wheel

Input/output interface

USB 、LAN、RS-232

Control type

Industrial computer control card

Screen

15″LCD touch-screen

Programming mode

G code, MDI, CAD list

Pitch compensation

Yes

Positioning accuracy

0.010mm

Repeated positioning accuracy

0.005mm

Working fluid pressure

0-10Mpa

Type of working fluid

Deionized water

Compressed air pressure

0.55~0.65MPa

Max. working current

30 A

Max. drilling speed

30 -120mm/min

Machine dimension

2300×2100×2500 mm

II. The machine characteristics:

III. Advantages of the machine

1. It is composed of main engine, CNC pulse power control cabinet, deionized water treatment system, etc.

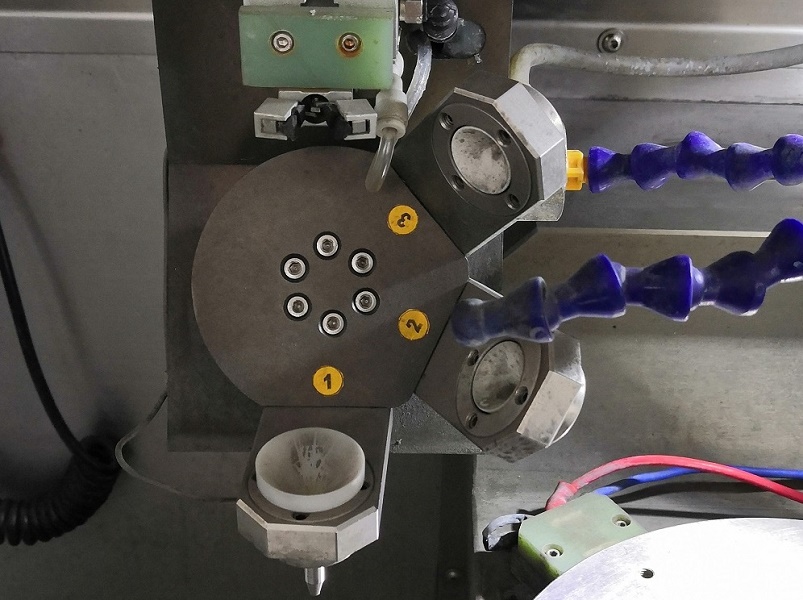

2. Main machine: composed of bed, column, X axis, Y axis, Z axis, S axis, B axis, C axis

3. CNC pulse power control cabinet: It is composed of industrial control computer, CNC system, touch screen, servo motors drive, machine tool electrical appliances, high-efficiency discharge pulse power supply, rocker arm waterproof and antipollution stainless steel keyboard control table, multi-function remote control hand box, etc.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap