- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

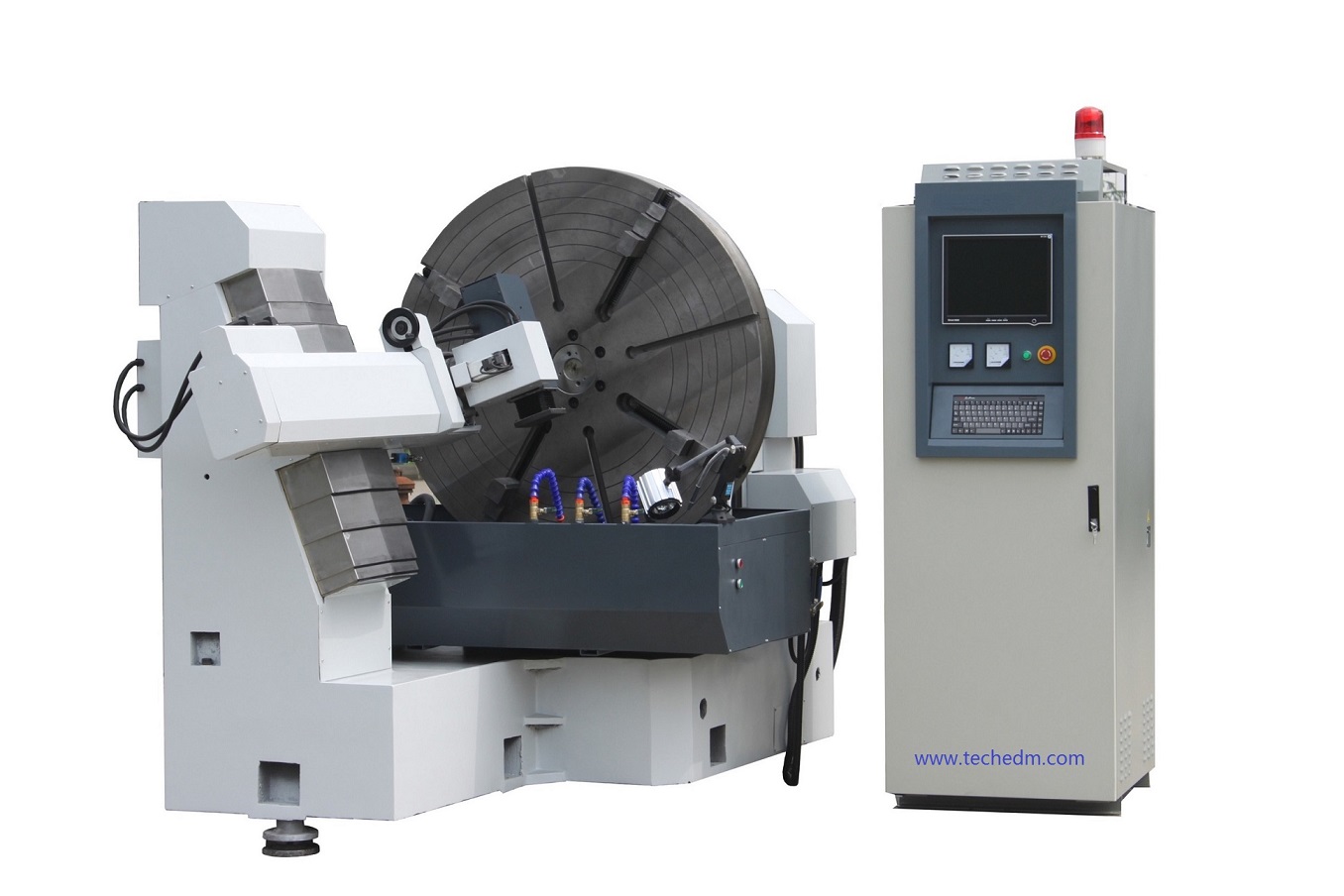

Sinker EDM for Tyre Mould Making

TM-130 is a 5-axis CNC precision Sinker EDM machine for tyre mould ring pattern making.

I. Benefits of the Sinker EDM machine for tyre mould ring pattern making:

Higher machining efficiency and lower usage cost.

II. Function of the Sinker EDM machine for tyre mould ring pattern making:

This machine is a special equipment developed for the processing of tyre mould ring pattern by adopting the method of EDM.

III. Advantages of the Sinker EDM machine for tyre mould ring pattern making:

1. The machine is controlled by IPC, five-axis CNC.

2. Z-axis position control, automatic conversion of processing speed.

3. Automatic indexing and indexing of the rotary table.

4. Automatic completion of machining process except for electrode change.

5. It can display the machining parameters, coordinate position and other information on the screen of the controller.

6. It can process half steel and full steel radial tyre molds.

7. There is a digital pulse power supply, and it can use copper or graphite electrode for machining.

IV. Quality Evidences of the Sinker EDM machine for tyre mold ring pattern making:

The Sinker EDM machine is our patented product and has been widely used in tyre mold making enterprises in China and overseas market.

V. Main Technical Parameters

Name/Specification: TM-130

Rotary table size: Ø1300mm

Spindle servo travel: 120mm

Max. electrode weight: 10kg

X-axis travel: 650mm

Y-axis travel: 50mm

W-axis travel: 300mm

Indexing accuracy of rotary table: 40"

Spindle swing angle: ±45º

Table load capacity: 2500Kg

Input power: 15KVA

Max. machining current: 200A

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap