- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

How to solve the problem of cutting large hardened alloys, like high chromium, high nickel alloy, and titanium alloy?

It is very difficult for many clients to cut off the large size hardened alloys with normal sawing machine efficiently. And the normal saw blade cost is very high too. How to solve the problem of cutting large hardened alloys, such as high-temperature heat-resistant alloys cutting, high chromium cutting, high nickel alloy cutting, titanium alloy cutting?

To solve this problem, we have developed EDS (electrical discharge sawing) machines. Here is one of our clients who orders one set of EDS machine with us this year. And the new EDS machine is installed successfully in the client’s workshop. The clients are very satisfied with the EDS machine cutting speed: 2300 sq mm/ min. Attached please find some pictures of the cutting test for your reference.

New EDS machine installed in our client's site

Cutting Jobs on EDS machine

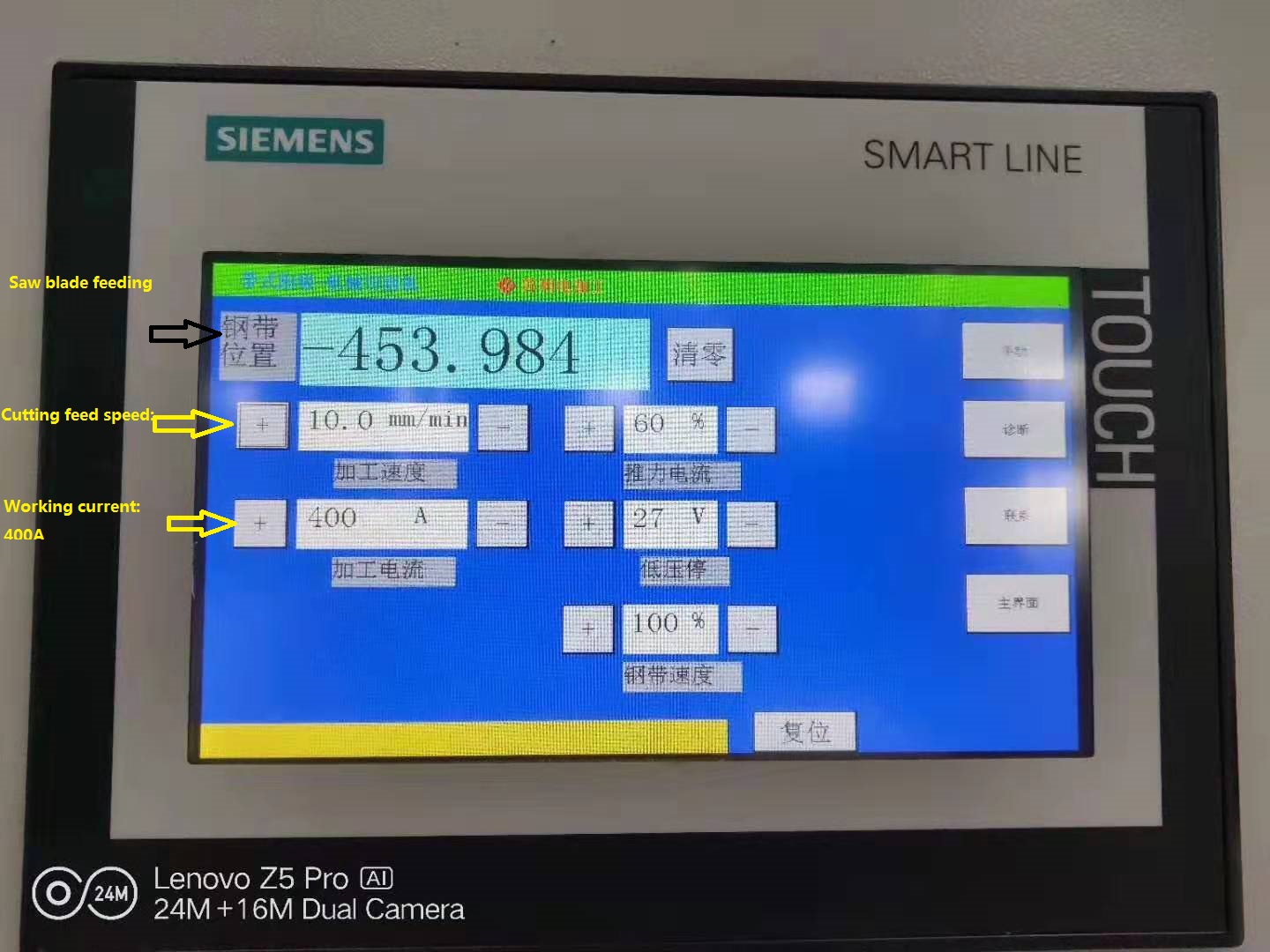

EDS machine Cutting Parameters

Job Description:

1. Diameter of the alloy job: 453mm

2. Material: High temperature steel alloy

3. Cutting off time: 69min

4. Speed: 2300 sq mm/min

5. Machinery tool: EDS machine (Electrical discharge sawing machine)

EDS Working Video as following link

https://live.kuaishou.com/u/3xaccu2rfzj9nee/3xk4h8zqd9ynnac?did=web_1a5217342ff6629fae8e90d967791320

If you have the similar jobs to cut in future, please feel free to contact us.

Have a Nice day.

Tech EDM Trade Co., Ltd

Tel: +86-512-88964165

Email: sale@techedm.com

Email: edmachining@hotmail.com

Add: No. 58 Huajin Rd, 215153, Suzhou, China

www.techedm.com

- Jobs of wire cut EDM

- Our Precision Phosphor Bronze Tubesare exported to Taiwan market successfully.

- With Electrical Discharge Saw Machine(EDS), you will get more benifits

- How to protect our trading partners’ benefit under the internet economic?

- EDS machine Cuts off ESR Ingots of Dia575mm Fastly!

- Frequent Questions about EDS (Electrical discharge sawing) machine

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2019-7-22

2019-7-22