- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

Frequent Questions about EDS (Electrical discharge sawing) machine

Our EDS machines attract a few of clients who have problems in cutting the high-temperature heat-resistant alloys, high chromium, high nickel alloy, titanium alloy. To help these clients to solve the problems, we have developed the EDS machines.

EDS machine installed in India client's workshop

Here are questions and answers that our clients asked before as follows:

Hello Wayne,

Thanks for your interest on our EDS machine (Electrical Discharge Sawing machine).

With EDS machine, you will get the following benefits as follows:

1. Improve the cutting speed greatly.

(Max cutting speed: 1800mm2/min, which is at least 2 times higher than band saw machine)

2. Save the cutting sawing blade cost greatly.

(A Mild steel blade is used as electrode, which is less than 10% of the normal sawing blade)

Bob

Hello Bob

Yes I received your information looks like a real nice saw!

I have a few Questions I was thinking about everything.

Q1: Please can you show me how you are able to get 500 amps to 1000 amps to that steel blade and wheels without everything turning red and melting everything ?or does everything stay cool with the water cooling ?

A1: The high frequent power supply system is our key technology. We apply two separate steps to reach the machining current 500A (on EDS350)/ 1000A (on EDS1100).

Step 1: with a special 3 phase linear transformer;

Step2: with a saturated magnetic amplifier.

Discharging Spark

The DC voltage is 32-50V during working. And the high frequent discharging power produces enough heat to gasify the work piece in a very short time. Meanwhile the water glass (coolant) will cool the cutting area and take away chips.

Q2: Is the Volts DC? Do the use on this blade? Is it High voltage or low voltage?

A2: The power is DC type, Voltage: 32V-50V.

Q3: Are they sensing the current or Volts for the gantry cutting feed speed?

Or does this blade stay cool with the salt /glass water?

A3: With Germany Siemens controller and Panasonic AC servo motor, we can control the discharge current and feeding speed in real time.

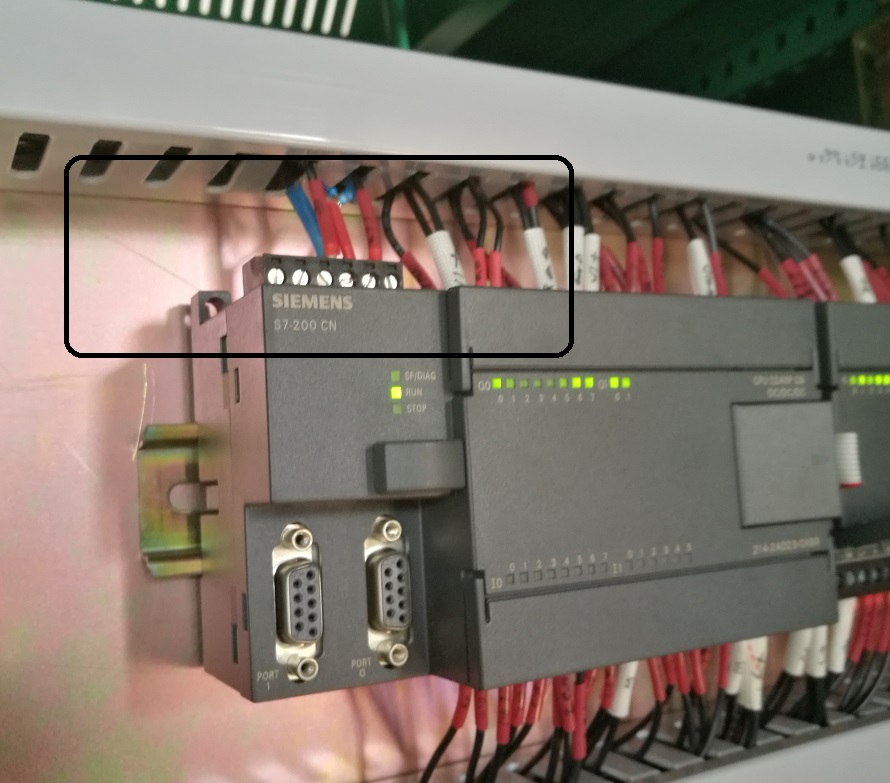

SIEMENS Controller

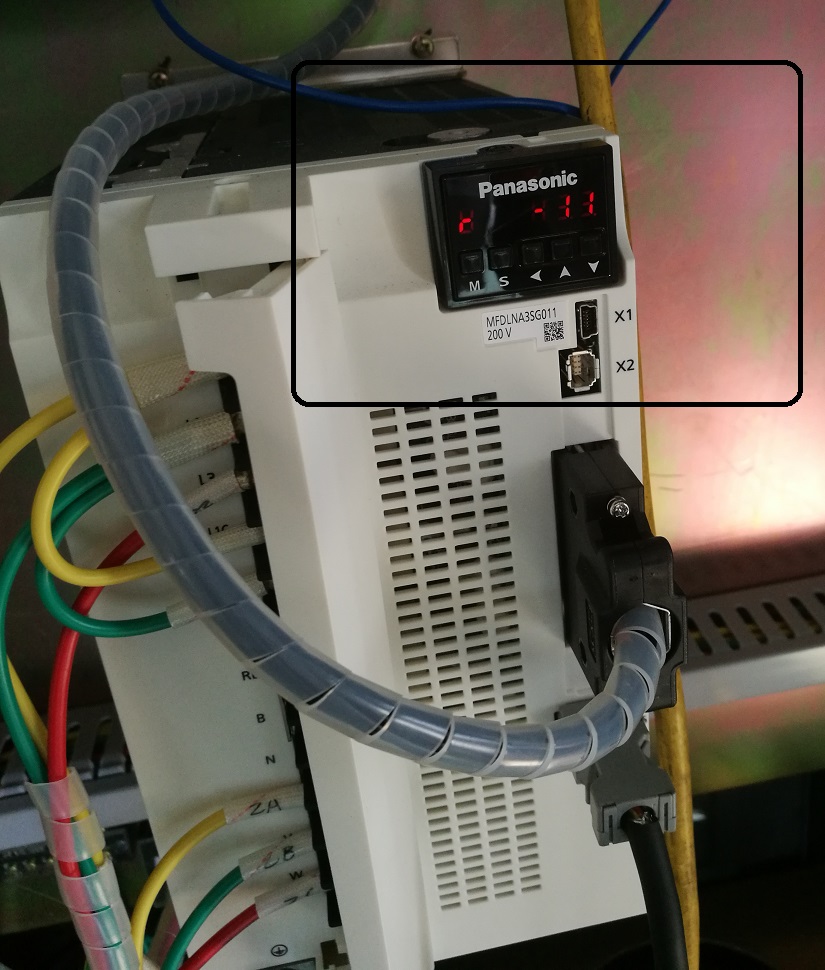

Panasonic AC servo motor and driver

Q4: Is there a steel tank to collect the cooling water?

A4: During working, the coolant (water glass) will flush to the cutting area with adjustable nozzles. Then the coolant returns to the collecting tank nearby the machine body. The tank is built near to the machine body. Some clients make a steel tank, which is placed in the pre-built tank. With the steel tank, it is easy for them to change the coolant.

Q5: Do they have to filter for this water?

A5: There is no filter for the water tank, because the EDS machine is used for larger size ESR ingots/ super alloys rough cutting instead of finishing.

Q6: How long do these blades last? Who do you purchase the blades from?

A6: The blade lasts time: at last time, when we cut off a bearing steel bar (dia350mm), the blade was still ok after cutting. In our test, one piece blade can cut off the special steel bar (Dia575mm) in around 150min.

EDS Cutting Sample of Dia575mm

Q7: Or can you make your own Mild steel blade using a band saw blade welder?

A7: The mild steel is a common part, similar to steel packing belt. You may get it easily at very low cost. Here the price is around 2 USD/pcs.

Mild steel blade

So many Questions as I look at this photo and watch that fire saw cutting that steel in the video!

Q8: Do you sell this blade welder?

A8: Yes, we will offer the mild steel welder as optional part.

Welder for Mild Steel Blade

Q9: Have you ever made a smaller fire saws?

A9: Now the smallest type we make is EDS350 which can cut max diameter: 350mm. If your job is smaller, you may place more pieces together to cut off them in one time.

Thank you very much for sharing these Quotes on this Awesome Fire Saws

For any more information about our EDS machines, please feel free to contact us.

EDS controller

Video of EDS machine as following link:

http://zhuozhou.m.kspkg.com/s/Xe5vaE-c

(To view this video, you may open it on a new webpage)

Have a Nice day.

Tech EDM Team

- The Reasons and Solutions of the Bad Roughness During the Finish Cutting

- Our Precision Phosphor Bronze Tubesare exported to Taiwan market successfully.

- Types of Plastic moulds

- With Electrical Discharge Saw Machine(EDS), you will get more benifits

- Customer's feedback about our product quality

- How to protect our trading partners’ benefit under the internet economic?

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2020-2-5

2020-2-5