- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

Vertical Spindle Rotary Table Surface Grinding Machine

High-Precision Combined Vertical Spindle Rotary Table Surface Grinding Machine

I. Benefits

1. Ultra-high machining efficiency: the "Heavy-Duty Workhorse." Ideal for rapid material removal, solving "from rough to flat" challenges with high throughput.

2. High rigidity and stability enable efficient grinding of large flat surfaces and discontinuous end faces of round or rectangular workpieces.

3. Low failure rate and easy maintenance due to standardized design of key transmission and conductive components, significantly reducing downtime and maintenance costs.

4. Wide applicability across industries such as refractory materials, air conditioning cylinders, stone, automotive, bearings, valves, saw blades, and glass. Suitable for processing various non-ferromagnetic materials including carbon steel, alloy steel, refractory bricks, ceramics, crystal, quartz, stone, and glass.

II. Features

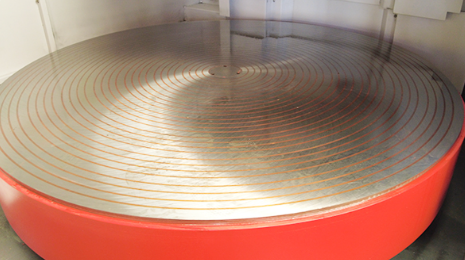

This high-precision combined vertical spindle rotary table surface grinding machine uses the end face of the grinding wheel for grinding, offering ultra-high machining efficiency.

The machine is equipped with a round electromagnetic chuck that rotates the workpiece. The electromagnetic chuck is mounted on a sliding saddle, which moves reciprocally along the bed guideways, facilitating convenient loading and unloading of workpieces.

The column and bed are connected by a three-point adjustment mechanism, allowing the grinding head angle to be adjusted for machining concave or convex surfaces across the entire workpiece.

The grinding head moves vertically along the column guideways, driven by an AC servo motor connected to a precision reduction mechanism and ball screw for accurate feed motion.

The grinding head spindle is powered by a waterproof, high-power built-in motor and supported by high-precision angular contact bearings, ensuring high cutting capacity and stable accuracy.

Machine castings are made of HT300 high-quality iron using resin sand casting, followed by annealing and stress-relief treatments, resulting in a stable structure and excellent workmanship.

III. Advantages

1. Z-axis Upgrade: The grinding head lifting mechanism has been upgraded from a traditional side-mounted servo motor with worm gear drive to a direct-coupled servo motor with a precision reducer and ball screw. This eliminates backlash, ensures sensitive feed without "tool drop," and is ideal for precision grinding.

2. C-axis Upgrade: The table rotation system now uses a standard integrated motor reducer directly engaging with the large ring gear, replacing the previous custom non-standard gearbox and multi-stage transmission. This reduces the failure rate and simplifies maintenance.

3. C-axis Conductive Structure Upgrade: The traditional carbon brush slip ring has been replaced with a Mobilon standard conductive slip ring mounted externally. Even if damaged, replacement is quick and easy without removing the table.

4. Y-axis Upgrade: The previous long-axis-driven gear and rack mechanism has been replaced with an external motor and precision reducer directly driving a ball screw. This ensures stable operation, high precision, and easy maintenance with an extremely low failure rate.

5. Y-axis Guideway Upgrade: The bed guideways have been optimized from a double-flat structure to a one-flat, one-V configuration, improving straightness and consistency of table movement.

6. Industrial Design Upgrade: Benchmarked against international brands, the machine features a fully enclosed high-end CNC sheet metal design after three rounds of industrial design iterations, giving it a premium and modern appearance.

IV. Evidence

The use of high-quality casting materials and processes ensures long-term structural stability.

Core transmission and guideway upgrades have been validated in practical applications for reliability.

Industrial design aligns with international high-end equipment standards, enhancing overall quality and user experience.

V. V. Specification

Specification

MGP7440

MGP7450

MGP7480

MGP74100

Work Table diameter

mm

400

500

800

1000

Electromagnetic table suction range

N/cm2

80-120

80-120

80-120

80-120

Max workpiece size (dia. x

height)

mm

400*200

500*300

800*300

1000*400

Sand tile size (OD x ID x H)

/Cylindrical

mm

150*80*25/ 300X150X25

150*80*25/ 300X280X25

150*80*25/ 450×380×25

150*80*25

Table Rotating speed

r/min

30-70

30-70

10-20

6-16

Table rotary motor

kw

1.5

1.5

4

2.2

Table movement distance

mm

250

260

450

570

Motor power for table movement

Kw

1.3

1.3

0.75

1.1

Table moving speed

m/min

1.6

1.6

3.5

3

Grinding head spindle speed

r/min

1400

1400

980

740

Rapid traverse speed of the

mm/min

300

300

300

300

Grinding head motor power

kw

11

11

25

25

Power of grinding head lifting motor (servo motor)

kw

1.3

1.3

1.3

1.3

Head feed rate (0.001mm, 0.01mm, 0.05mm)

Times

X1X10X100

X1X10X100

X1X10X100

X1X10X100

Pump motor power

kw

0.12

0.12

0.25

0.25

Total machine power

kw

15

15

30

52

Machine weight (approx.)

Ton

2.5

2.5

6

7.5

Machine dimension

mm

2300×1000×1800

2300×1000×1800

2450*1180*2230

3010*1500*2230

power

grinding head

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap