- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

EDM machine for Metal Bonded Diamond Grinding Wheel Forming and Repairing

EDM Machine for Metal Bonded Diamond Grinding Wheel Finishing

I. Function:

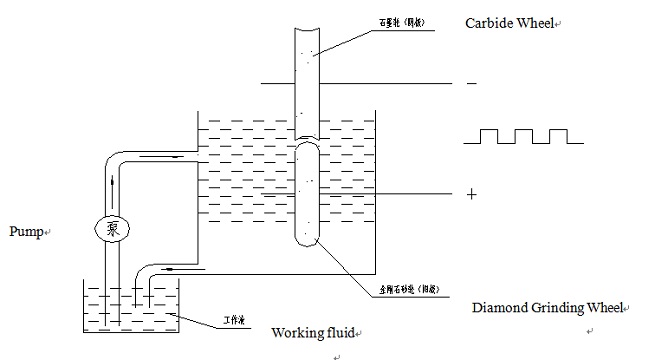

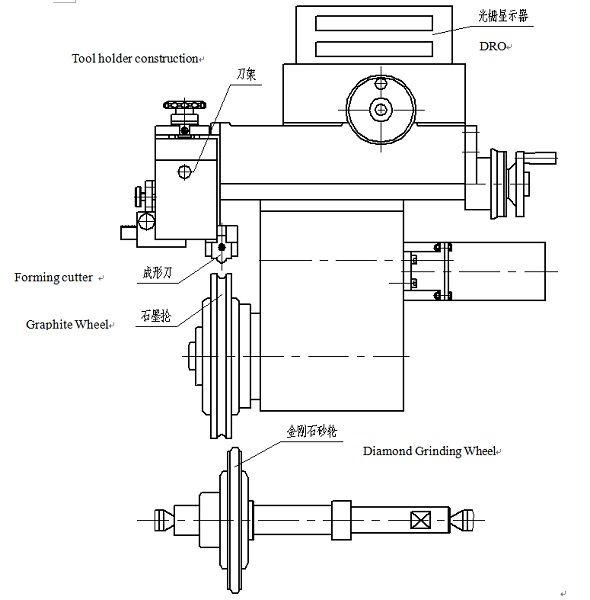

This special EDM machine is mainly used for reforming and repairing the metal bonded diamond grinding wheel of the high speed steel wire/rod roll rings grinding machine, adopting the principle of the electrical discharge machining.

To repair and reform the R-sharp groove or V-sharp groove on the carbide roll rings of the high speed steel wire/rod roll milling machine, we have designed and produced two types of CNC machines: CNC grinding machine of the roll ring and the CNC EDM repairing machine of diamond grinding wheel.

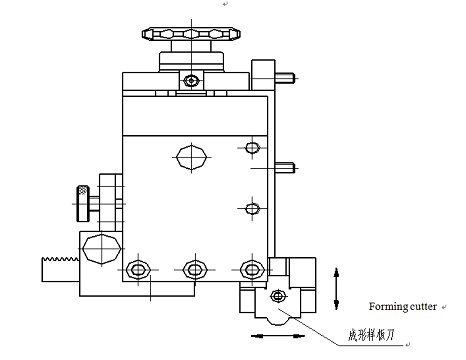

Firstly a cutting tool is cut with wire cut EDM machine.

Secondly the graphite wheel is cut with the above cutting tool on the EDM repairing machine.

Thirdly the metal bonded diamond grinding wheel is repaired and reformed with the graphite wheel as the electrode on the CNC EDM repairing machine too.

II. Advantages:

The machine has the following advantages, comparing the silicon carbide wheel grinding machine:

1. the influence of human factors is smaller and the operation is easier;

2. the repaired metal bonded diamond wheel has a higher accuracy and better reliability;

3. the repairing metal bonded diamond wheel is sharper, with a better chip capacity and higher grinding efficiency;

4. the repaired metal bonded diamond grinding wheel is shape accuracy and good durability;

5. The machine is user friendly and has a longer usage life.

III. The benefits you can get with our EDM machines:

1. You can sharpen the metal bonded diamond grinding wheel efficiently;

2. You can make the metal bonded diamond grinding wheel sharper, higher accuracy and better reliability;

IV. Evidences:

1. The machine has won national patents, the Ministry of Machinery Technology Progress Award, and the certificate of high-tech products.

2. The machines are popular in many high speed steel wire/rod plants in China, such as Shenyang high speed steel wire plant, Pan steel plant, Bao steel plant, Great wall steel plant, Qiqihar steel, etc.

3. The machines have been exported to overseas markets like Thailand, Vietnam, Iran, Malaysia, Philippines, Nigeria, etc.

V. Specification:

|

Specification of the diamond grinding wheel repairing EDM machine |

||

|

Diamond grinding wheel EDM machine |

Model |

DCS-003A |

|

Parameters |

Unit |

Value |

|

Outer diameter of repairable diamond wheel |

mm |

Ø40- Ø400 |

|

Width of repairable diamond wheel |

mm |

5-65 |

|

Type of repairable diamond wheel groove |

* |

any type |

|

Dia. of repairable diamond wheel inner hole |

mm |

≤Ø60 |

|

Working fluid |

* |

EDM fluid |

|

Machine size (L* W * H) |

mm |

1270 * 1565 * 1628 |

|

Machine weight |

KG |

2000 |

|

Processing accuracy: |

||

|

Cylindrical deviation of out circle |

mm |

0.01 |

|

Outer diameter tolerance |

mm |

±0.005 |

|

Hole diameter tolerance |

mm |

±0.01 |

|

Hole depth tolerance |

mm |

±0.005 |

|

The best surface roughness for grinding |

um |

Ra≤0.4 |

|

Position center tolerance of roll ring face |

mm |

±0.01 |

VI. Main parts of the machine:

The machine is composed of main body, column, working fluid tank, head frame, tail frame, transmission box, working fluid system, large protective cover, etc.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap