Home » What is the use of the small hole drilling EDM machine?

Categories

News

- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

Our newsletter

What is the use of the small hole drilling EDM machine?

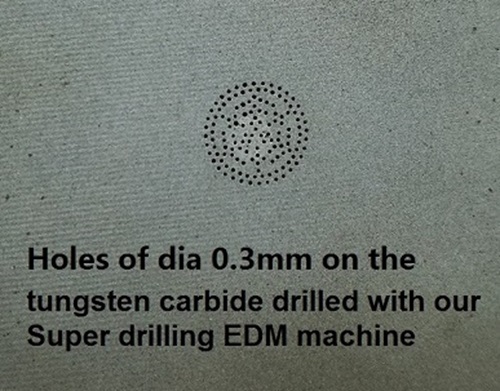

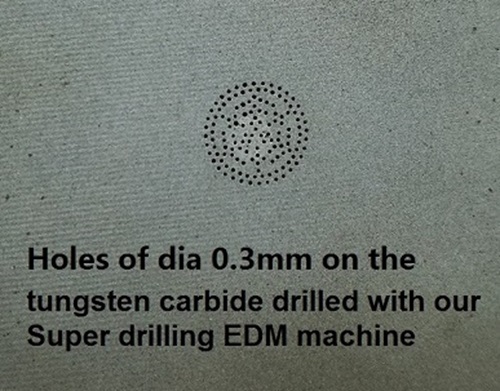

Small hole drilling EDM (Electrical Discharge Machining) machines are primarily used for creating small, precise holes in extremely hard materials. Here are some common uses:

Aerospace Industry: EDM machines are often employed in the aerospace industry for creating small holes in turbine blades, engine components, and other intricate parts where traditional drilling methods are not feasible due to the hardness of the materials involved.

Medical Industry: These machines are used to create precise holes in medical devices such as surgical instruments, implants, and dental tools.

Tool and Die Making: Small hole EDM machines are utilized in the manufacturing of molds, dies, and other tooling components where intricate holes are required for various purposes.

Electronics Industry: In the electronics industry, these machines are used for producing small holes in printed circuit boards (PCBs) and other electronic components with high precision.

Automotive Industry: Small hole EDM is employed in the automotive industry for creating injector nozzles, fuel system components, and other parts that require precise, small-diameter holes.

Mold Making: In mold making for plastic injection molding or die casting, small hole EDM is used for creating cooling channels and other intricate features within the mold cavity.

Overall, small hole EDM machines offer the capability to produce high-precision holes in extremely hard materials, making them invaluable in industries where such requirements are common.

Aerospace Industry: EDM machines are often employed in the aerospace industry for creating small holes in turbine blades, engine components, and other intricate parts where traditional drilling methods are not feasible due to the hardness of the materials involved.

Medical Industry: These machines are used to create precise holes in medical devices such as surgical instruments, implants, and dental tools.

Tool and Die Making: Small hole EDM machines are utilized in the manufacturing of molds, dies, and other tooling components where intricate holes are required for various purposes.

Electronics Industry: In the electronics industry, these machines are used for producing small holes in printed circuit boards (PCBs) and other electronic components with high precision.

Automotive Industry: Small hole EDM is employed in the automotive industry for creating injector nozzles, fuel system components, and other parts that require precise, small-diameter holes.

Mold Making: In mold making for plastic injection molding or die casting, small hole EDM is used for creating cooling channels and other intricate features within the mold cavity.

Overall, small hole EDM machines offer the capability to produce high-precision holes in extremely hard materials, making them invaluable in industries where such requirements are common.

Related news

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2024-5-13

2024-5-13