- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

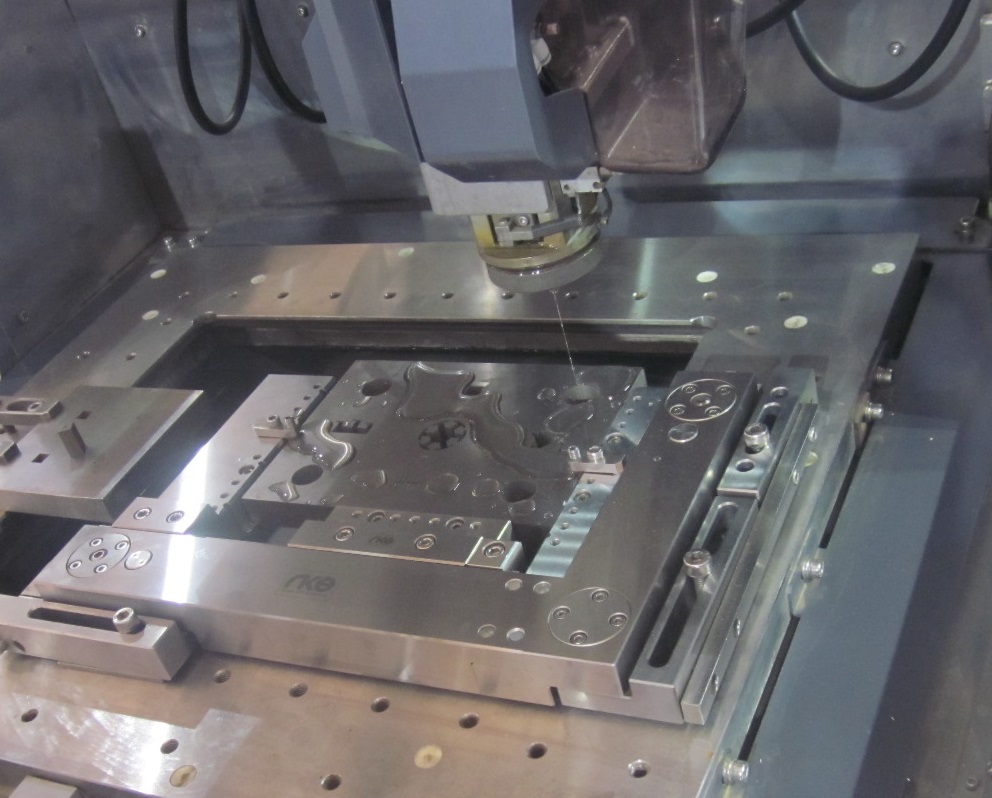

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

How to remove the wire lines on the wire cutting EDM surface?

1. The quality of the EDM wire is not good. ---we suggest you change the quality brand EDM wire.

2. The kind of jobs material are not suitable or impurity is too much--- please change the material.

3. Inner stress deformation which leads wire lines appear—please try to pre-treat the job material to avoid the deformation.

4. The temperature of the working liquid is too high or the environment is changing greatly—you have to control the temperature by the air conditioner.

5. Vibration condition—please try to improve it.

6. Power feed contacts wears off too much—try to rotate them or change new ones.

7. The coolant near to the upper and down wire guides are not enough,--- try to clean these parts.

8. The coolant is too dirty --- wash and clean the water tank and the working areas and change the new coolant.

9. Check if the electrical discharging condition is stable or not, or the short happens and wire returns back or not during the half-finish or finish cutting? If necessary, try to increase UHP value 1 to 2.

10. If the wire line is deep, change the Smode to 10, and increase 2 on UHP value.

11. During the finish cutting, if the current and voltage are normal, but the cutting speed is lower, please try to reduce the offset value.

12. The coolant condition is not good, like water pressure is weak, or water share is bad—check the upper and down water nozzles are broken or not.

13. The wire tension is not stable.—try to adjust the wire running speed and tension.

Hope above information is helpful to you. For any more information about solutions of the wire EDM machines, please feel free to contact us.

Thanks,

Tech EDM Team

1. Wire EDM workpiece

2. Bigger taper cutting Job

- Opening of the 9th CCMT

- IMTS2016 will be held in Chicago in Sept12-17,2016

- Larger tapper wire EDM cutting for X leafter and Radar emitter making

- What are the Solutions of the taper cutting error for the straight jobs with Wire EDM machine?

- Why do customers select us (Tech EDM) as their partners?

- How to solve the wire broken problem when cutting Aluminum jobs?

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2016-11-15

2016-11-15