- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

How to select the electrode tubes for your small hole EDM machines?

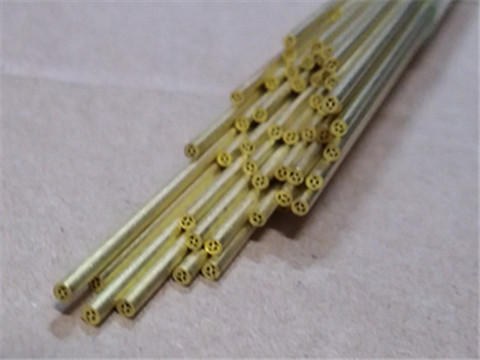

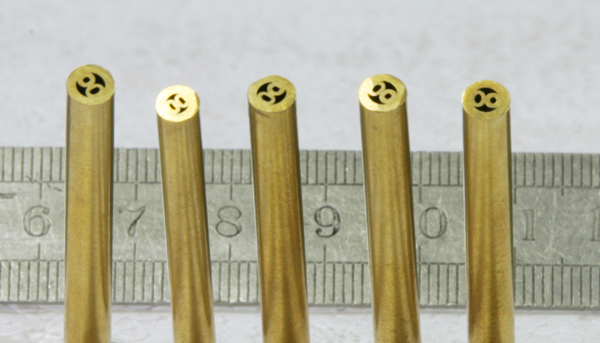

Key points: There are two kinds of tubes according the materials: brass tube and copper tubes. And the brass/copper tube electrodes can be divided into two models: Single Hole Electrode Tubes and Multi-Channel Electrode Tubes.

Brass tubes:

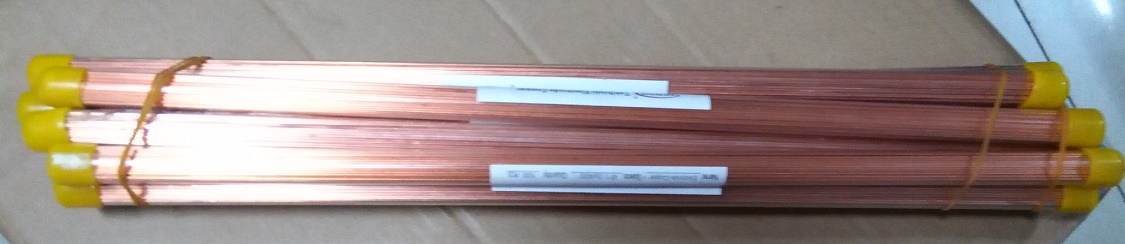

Copper tubes

Normally we suggest customers select the electrodes according to the workpiece material and the hole types: a” thru hole” or a “blind hole”. If your workpiece is extremely hard metals such as Carbide, or Tungsten Carbide, copper electrodes are recommended, if the material is normal material, such as mould steel, brass tubes are better.

If the hole is thru hole, single hole electrode tubes are used. For the blind hole drilling, the multi channel electrode tubes are used.

There are many different applications that call out for EDM Small hole drilling. There are also many different variables about the material types being machined and the settings you use for that particular EDM Electrode.

Our EDM Electrodes are designed to work with ALL types of EDM Equipment and ALL types of EDM Machines.

How well our Top Quality products do on your Small Hole EDM machine depend on TWO simple variables:

1- The type of material that the EDM electrode is comprised of; which is either Brass Tubing or Copper Tubing.

2- What type of Flushing Hole or Internal Diameter is through the EDM tubing. This is either a single hole diameter with no other internal walls or is a multi-channel type internal hole with multiple walls throughout the length of the electrode.

Let’s first discuss the two main types of EDM tubing material:

Brass tubing & Copper tubing.

Brass Electrodes | Brass EDM Tubing

Brass EDM Tubes are used on the largest variety of electrically conductive materials and metals to small hole drill. If you are not quite sure which electrode material to start out with, Brass would typically cover MOST material types. Because of the molecular composition of Brass, it will remove material at the fastest rates when applied to different alloys, tool steels, stainless steels and rare metals.

Brass electrodes tend to wear out much faster compared to Copper Electrodes, which means the Brass electrode will disintegrate at the point of which the spark leaves the electrode to the point of contact on the work-piece, this should be taken into consideration on long running hole burns or EDM Holes that are very deep.

When EDM Drilling extremely hard metals such as Carbide, or Tungsten Carbide; Brass tubing is not recommended because of it’s fast disintegration rate.

Copper Electrodes | Copper EDM Tubing

Copper tubing can be used to EDM hole drill in all material types. Copper, because of its molecular composition tends to last longer during hole burning compared mostly to Brass.

One unique characteristic of Copper is that it is ideal when small hole drilling through very hard materials such as Carbide and Tungsten. This is because it has a slower and steadier burn rate that will measure up stronger. When EDM holeburning through a depth to width ratio of greater than 100 to 1 this also tends to be ideal because a more controlled hole burn will leave a more accurate and straighter hole.

The Copper tubing that we supply is 99.995% pure.

Single Hole Electrode Tubes vs. Multi-Channel Electrode Tubes

Another variable which determines the ultimate success of the electrode properly EDM Hole Burning through the material or work piece is if the Brass Electrode or Copper Electrode tube has a “single hole” or a “multi channeled hole” running directly through the ID or (Internal Diameter) of the electrode.

Basically put; in order for an electrode to perform the way it’s supposed to, it depends on the type of hole going through the center of the electrode. This type of hole has a few purposes. One purpose is to direct water or coolant through the center of the electrode. This keeps the entire length of the Brass or Copper Tube from overheating and burning up. If the electrode heats up too much it can become “soft” and warp thus not creating a straight line or a consistent and accurate EDM Hole.

The main reason that determines whether an EDM Electrode tube would have a “single hole” or a “multi-channel” / “coreless” hole is that when a hole is EDM Machined into a part it could be a “thru hole” or a “blind hole”. Blind holes are not drilled complete to the other side so a “slug” or a piece of material is still left untouched at the bottom of the hole.

Single Hole & Single Channel EDM Tubes

![]()

Brass EDM Tubing and Copper EDM Tubing can both be Single Hole. Single Hole Electrodes are usually cheaper in price because there is less of that material in the electrode. Single hole tubing is recommended only for hole burning applications that require a hole to be drilled entirely through the part.

If you have further questions or would like clarification in regards to your machine, application or electrode type, please contact us for further questions. We would be very glad to help you and would appreciate any feedback you have to offer.

Multi-Channel EDM Tubes

![]()

Multi-Channel Tubes are used for

EDM Machining a blind hole. The internal channels are designed to burn away any

material left at the bottom of the hole. This is because the electrode has

material inside the flushing hole that is used to disintegrate the work piece

material.

Since the electrode spins around at a very high rate, the internal diameter has

electrode material to disintegrate metal in the center of the cavity. This will

not leave any slug or piece of material at the bottom of the hole.

We can offer you various kinds ofhigh precision tubes at a reasonable price. These tubes are popular in Over seas market, like Germany, France, Spain, USA, Korea, Taiwan, etc.

Hope above information is helpful to you. For any more information about solutions of the wire EDM machines, please feel free to contact us.

Thanks,

Tech EDM Team

- Our coiled brass tube is very popular for its fine quality in overseas market

- How to remove the wire lines on the wire cutting EDM surface?

- Our EDM Hole Popping machines are popular in European market

- Our EDM Coated Wire quality is acceptable to European clients.

- How to make a program for Multi times cutting on Wire EDM machine?

- How to reduce the usage cost of wire cut EDM machines?

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap

2016-12-20

2016-12-20