- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

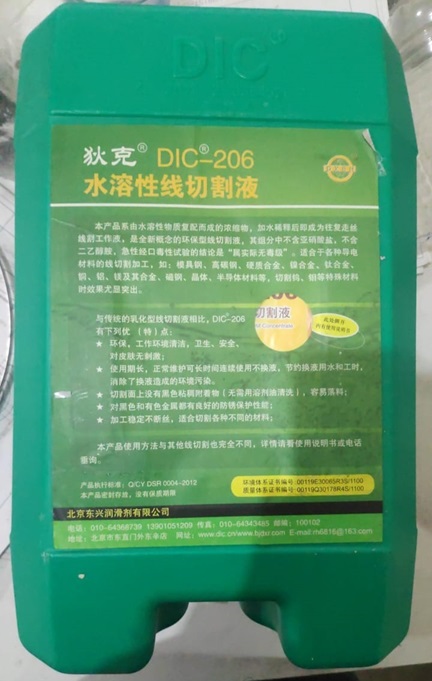

DIC-206 Wire EDM Fluid

Introduction:

DIC-206 is energy-saving and emission-reduction type Wire Cut EDM fluid. The formula of DIC-206 Water-Soluble WEDM Concentrate is completely made up of water-soluble materials. Electrical corrosion products can disperse in the water solution quickly, and could be separated after sedimentation and filtration.

Rat oral acute toxicity tests result is "non-observed toxicity". No black sludge will emerge on the cutting surface of workpiece. It is the technical leading working fluid for “Wire Cut EDM”,with outstanding features of health and safety and so on. All of the RoHS Directive items testing results are “N/D” (not detected).

Working Concentration:

Concentrate has to be diluted by pure water (DI water). Suitable working concentration is recommended in the operating manual (1:6 with water). It shall be checked by handhold refractometer WY-20R. Supplementing water is necessary every shift in daily work. After that, checking and judging if supplementing DIC-206 concentrate is necessary must be done. Since the boiling points of effective components in working fluid are higher than water, the concentration will generally increase if water is not supplemented.

Application:

1.

A suitable filter (we can offer)

must be installed on the exit of circulating pump to remove larger particles of

electrical corrosion products. Then, the effect of cutting process could be

ensured, and the using term of working fluid could be long.

2. DIC-206 cannot be blended with other Wire EDM fluids for use.

3. When using DIC-206 instead of emulsion coolant, the following steps shall be

done:

A. The whole fluid feeding and circulating system, after draining off

the previous emulsion, shall be cleaned thoroughly with

suitable cleaning agent.

B. The machining parameters shall be regulated: increasing the

electric current and the feed rate properly.

4. If there are some oxidation products leaving on the machined surface of

workpieces after operating with DIC-206, use alcohol to erase. Or, grit

blasting can get better effect.

5. Rust protection of workpieces and other ferrous metal parts must be

done every week, using 16.7% working fluid coating on the surfaces to be

protected with brush or other adequate tools.

6. Electrical corrosion products that leave on the bridge board,

bracket and operating platform shall be cleaned up often (about one or two

times one week).

Note:

1. We highly recommend

you to use DI water!

2. It is possible to appear electrochemical etching

occurring on the aluminum wire reservoir if the surfaces of aluminum wire

reservoir have not been hardened.

Storage: It

shall be sealed and stored indoor in the temperature 5~50℃. If you can store appropriately,

no shelf-life will be required.

Packing: Net

weight 10kg (plastic bucket). GW:10.75Kg; 50 Buckets per pallet.

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap