- European clients are satisfied with our customized End Milling Tools

- How to select grinders between Vertical Spindle Rotary Table Grinders VS Horizontal Spindle Rotary Table Grinders?

- How to choose the electrode material for your EDM machine? Graphite Electrodes or Copper Electrodes?

- Unlock Precision Manufacturing at CIMT 2025: Discover Cutting-Edge EDM Solutions

- Applications of Wire Cutting Machines

- What are the Advantages of wire EDM Machine with Auto wire threading?

- What are the Characteristics of Working Fluid for Wire EDM Machine?

- Merry Christmas &Happy New Year of 2025!

- What is the working principle of Chemical Deburring (Electrochemical Deburring)?

- What are the differences between the Wire Cut EDM machine and the Laser Cutting Machine?

Electro Chemical Deburring Machine

I. Introduction of ECD(Electrochemical deburring) machine:

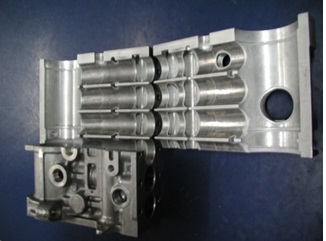

To solve burring problem in the cavity type metal jobs, we have recently developed the Electro chemical deburring machine, with electrochemical discharging principle. Our ECD machines are mainly used to remove debur automatically and selectively inside of the metal jobs like pump body, valve body, connecting rod, crankshaft, plunger needle valve couple and gear in pneumatic, hydraulic, engineering machinery, oil nozzle pump, automobile and engine industries, etc.

II. Benefits you will get with ECD machines:

Benefit A. Higher efficiency of deburring in cavity type metal jobs.

Benefit B. Safer to the metal finish surface.

Benefit C. Easier to remove the inner cavity burrs that is difficult for mechanical methods.

III. Advantages:

1. It is suitable for removing internal burrs inside of metal jobs which are difficult to remove internal burrs with mechanical methods.

2. Small rounded corners can be formed at the intersection of holes or edges.

3. Safe to the job finish surface and operators( Because the neutral inorganic salt, sodium nitrate is used aselectrolyte).

4. High deburring efficiency, it takes 2 to 3 minutes to remove the inner burrs only.

5. Burrs can be removed in a serial of metal jobs or different areas at the same time.

IV. Specification

|

Model No. |

ECD6032 |

ECD60150 |

ECD10050 |

|

Worktable size(mm) |

320*600 |

Dia1500 |

500*1000 |

|

Spindle travel(mm) |

200 |

70 |

0 |

|

Output voltage(V) |

DC 0-24V |

DC 0-24V |

DC 0-24V |

|

Max output current(A) |

300-2000 |

600 |

600-1500 |

|

Tank capacity(L) |

1500 |

1500 |

1500

|

- Home - About us - New products - News - FAQ - Inquiry - Contact us - Sitemap